Cutting-Edge Bulletproof Plates: Silicon Carbide and Boron Carbide Revealed!

By:Admin

Introduction (50 words):

In recent years, personal defense technology has taken a significant leap forward with the emergence of advanced ceramic compounds. Among these, Silicon Carbide (SiC) and Boron Carbide (B4C) stand out as highly effective materials for bulletproof plates. These groundbreaking innovations are revolutionizing the strength and performance of bullet-resistant vests, empowering individuals to face threats with greater confidence and safety.

Body:

1. The Rise of Advanced Ceramic Compounds in Personal Defense (150 words)

With an increasing demand for lightweight and stronger body armor, the progress made in the field of advanced ceramics has had a significant impact on personal protection. Silicon Carbide and Boron Carbide, in particular, have become popular materials used in the production of bulletproof plates due to their extraordinary properties. Being lightweight and remarkably hard, these compounds offer a balance of strength and flexibility, making them ideal for bullet resistance.

2. The Remarkable Properties of Silicon Carbide and Boron Carbide (200 words)

Silicon Carbide, also known as SiC, is a material that possesses exceptional high-temperature and corrosion resistance properties, making it suitable for a wide range of applications. Due to its hardness and low density, it not only resists bullet penetration but also reduces the weight burden on the wearer. Boron Carbide, or B4C, is another compound that excels in terms of hardness, making it effective against multiple threats. Its light weight and impressive ballistic properties make it highly desirable in both military and civilian bulletproof armor.

3. The Application of Silicon Carbide and Boron Carbide in Bulletproof Plates (200 words)

Bulletproof plates made from Silicon Carbide and Boron Carbide have gained immense popularity due to their remarkable durability and high level of protection. These plates are typically embedded in tactical vests or armor carriers, providing reliable coverage to vital organs and minimizing blunt force trauma. With advancements in manufacturing technology, the thickness and weight of these plates have been substantially reduced, without compromising their protective capabilities.

4. Market Impact and Future Potential (150 words)

The adoption of Silicon Carbide and Boron Carbide bulletproof plates has disrupted the personal defense market by offering a superior alternative to traditional protective materials. Increased investments in research and development have allowed companies to further enhance the performance of these advanced ceramic compounds. The market for bulletproof plates is expected to witness significant growth in the coming years, as these materials become more affordable and accessible to both military personnel and civilian users alike.

Conclusion (100 words)

Silicon Carbide and Boron Carbide bulletproof plates have emerged as groundbreaking innovations in personal defense technology. Offering superior resistance against penetration while remaining lightweight, these advanced ceramic compounds have revolutionized the strength and performance of bullet-resistant vests. With the increasing popularity of these materials, the personal defense market is witnessing a significant transformation. As research and development efforts continue to push the boundaries of these compounds, we can expect even more impressive advancements in bulletproof plate technology, ensuring enhanced safety and protection for individuals facing imminent threats.

Company News & Blog

Guide on selecting suitable chute liner for optimal performance

Choosing the right chute lining material is an essential step during the design consideration process. The selection of a suitable chute lining material can significantly impact the performance, durability, and maintenance requirements of the chute. In this blog post, we will discuss the importance of choosing the right chute lining material, specifically for coal chutes. Additionally, we will explore various factors that should be taken into account when selecting coal chute lining materials.Coal chutes are used in industries such as mining, steel, power generation, and cement manufacturing, where coal needs to be transferred from one location to another. These chutes are subjected to extreme conditions, including high abrasion, impact, and temperature variation. Therefore, it is crucial to choose a chute lining material that can withstand these challenges and provide maximum longevity.When selecting a chute lining material for coal chutes, the following factors should be considered:1. Abrasion resistance: Coal is a highly abrasive material and can cause significant wear and tear on chute surfaces. Therefore, the lining material should have excellent abrasion resistance to ensure prolonged service life.2. Impact resistance: Coal can also cause impact damage to chute surfaces, especially during the loading and unloading process. The lining material should possess good impact resistance to withstand such forces without cracking or breaking.3. Temperature resistance: Coal chutes are often exposed to high temperatures due to the combustible nature of coal. Therefore, the lining material should be able to withstand elevated temperatures without undergoing any structural or chemical degradation.4. Corrosion resistance: Coal contains sulfur and other corrosive elements that can lead to corrosion of metal chutes. Hence, it is advisable to choose a lining material that has excellent corrosion resistance properties to prevent any damage or deterioration of the chute structure.5. Material flow properties: The lining material should possess a smooth surface to promote the smooth flow of coal through the chute. Any rough surfaces or protrusions can cause material hang-ups or blockages, leading to production inefficiencies.Considering these factors, ceramic chute lining materials are often preferred for coal chutes due to their exceptional properties. Ceramic materials, such as alumina ceramics, offer superior abrasion resistance, impact resistance, and temperature resistance. They are extremely hard and can withstand the abrasive nature of coal, reducing wear and tear significantly. Alumina ceramics also have excellent high-temperature resistance, ensuring the longevity of coal chutes in industries where coal combustion occurs.Moreover, ceramic chute linings provide excellent corrosion resistance, eliminating the concerns related to corrosion caused by the sulfur content in coal. Their smooth surface properties help in reducing material hang-ups or blockages, improving the material flow efficiency. Additionally, ceramic linings can be easily customized and installed to fit specific chute designs.In conclusion, the selection of the right chute lining material is of utmost importance when designing coal chutes. Considering factors such as abrasion resistance, impact resistance, temperature resistance, corrosion resistance, and material flow properties, ceramic materials, especially alumina ceramics, are an excellent choice for coal chute linings. Their exceptional properties ensure extended service life, reduced maintenance requirements, and improved production efficiency. If you are looking for high-performance chute lining materials for your coal chutes, consider ceramic options to provide you with a reliable and long-lasting solution.

Cyclone Liner Manufacturing: All You Need to Know About the Process

Title: Revolutionizing Cyclone Liner Manufacturing: Breakthrough Technology Improves Efficiency and DurabilityIntroduction:In a remarkable achievement, an industry-leading cyclone liner manufacturer, is set to revolutionize the market with its groundbreaking technology. Committed to improving efficiency and durability, this pioneering company has developed a cutting-edge cyclone liner that promises increased performance and longer lifespan. By combining advanced materials, meticulous craftsmanship, and a focus on customer satisfaction, they have positioned themselves as a frontrunner in the industry. Let's delve into the details of this game-changing development.Redefining Cyclone Liners:Cyclone liners play a crucial role in industries such as cement, mining, and power generation by separating fine particulate matter from gas or air streams. Traditionally, these liners have faced challenges like wear and tear, frequent replacements, and compromised performance. However, with its proprietary technology, this innovative manufacturer is all set to disrupt the cyclone liner market forever.State-of-the-Art Manufacturing Process:The company employs a state-of-the-art manufacturing process that utilizes an amalgamation of advanced materials and precision engineering. Through meticulous research and development, their engineering team has cured issues that were previously considered inevitable in cyclone liners. The result is a liner that boasts enhanced resistance to wear, abrasion, and corrosion.Material Innovation:One of the key factors contributing to the superior performance of their cyclone liners is the innovative material utilized in their manufacturing process. The company's dedicated R&D team identified and developed a unique blend of high-density ceramics and polymers. This combination enables the liner to withstand extreme temperatures, ensuring longevity and maintaining peak performance even in the harshest environments.Enhanced Efficiency:By significantly minimizing the wear and tear associated with traditional cyclone liners, these new liners exhibit an unprecedented increase in efficiency. This groundbreaking development offers tangible benefits to industries, such as reduced downtime and maintenance costs. Increased efficiency translates into improved productivity, allowing businesses to optimize their operations and maximize profitability.Unrivalled Durability:Durability has always been a concern in cyclone liners, as the high-speed particulate matter takes a toll on their surfaces. However, the manufacturer's cutting-edge technology has addressed this issue head-on. Their liners boast exceptional durability, and extensive testing has shown they outlast traditional liners by a significant margin. Businesses can expect a drastic reduction in replacement costs, delivering long-term savings and enhancing operational efficiency.Customer-centric Approach:This leading cyclone liner manufacturer has built its reputation on a customer-centric approach. They understand the unique requirements and challenges faced by industries that rely on cyclone liners. By working closely with their clients, they develop tailored solutions that meet their specific needs. Their commitment to providing exceptional service has earned them a loyal customer base and widespread industry recognition.Driving Sustainability:Beyond their commitment to performance and durability, this manufacturer is also fervently dedicated to sustainable practices. Their cyclone liners are designed to minimize environmental impact while maximizing efficiency. By utilizing renewable and recyclable materials, they reduce the carbon footprint associated with their operations. This commitment to sustainability allows industries to achieve their goals while adhering to environmental regulations and reducing waste.Conclusion:With its groundbreaking cyclone liners, this manufacturer has set a new standard in the industry through its cutting-edge technology, unparalleled durability, and enhanced efficiency. By combining state-of-the-art materials with precision engineering, they are redefining cyclone liner manufacturing. With a focus on customer satisfaction and sustainable practices, this leading manufacturer is poised to transform the global cyclone liner market, benefiting industries worldwide.

Discover the Latest Technology in Fuel Oil Burner Spray Nozzles

Title: Innovative Fuel Oil Burner Spray Nozzle Redefining Efficiency and SustainabilityIntroduction: With a continued push towards green and sustainable solutions, companies across industries are actively seeking innovative and eco-friendly alternatives. In line with this trend, the revolutionary Fuel Oil Burner Spray Nozzle, developed by a leading manufacturer in the energy sector, promises to transform the combustion process with heightened efficiency and reduced environmental impact.Paragraph 1:In today's fast-paced world, energy efficiency is key to both cost-effectiveness and sustainability. Recognizing this, the unnamed manufacturer introduces its groundbreaking Fuel Oil Burner Spray Nozzle, engineered to optimize the combustion process and minimize energy consumption. The nozzle's unique design positively impacts industries such as heating, power generation, and manufacturing.Paragraph 2:A distinguishing feature of the Fuel Oil Burner Spray Nozzle is its ability to finely atomize fuel oil, generating a fine mist that ensures complete combustion. With this nozzle, the manufacturer addresses the longstanding challenge of incomplete combustion, reducing harmful emissions and enhancing overall energy efficiency. The nozzle's innovative design delivers remarkable heat transfer capabilities, maximizing the utilization of fuel and reducing energy wastage.Paragraph 3:The Fuel Oil Burner Spray Nozzle's efficiency is further augmented by the integration of advanced technologies and streamlined manufacturing processes. The precision engineering ensures a consistent spray pattern, resulting in a steady and efficient combustion process. Moreover, the nozzle is constructed using high-grade materials to enhance durability, making it a reliable solution for long-term use in industrial applications.Paragraph 4:In an era with increasing environmental concerns, reducing harmful emissions is of paramount importance. The Fuel Oil Burner Spray Nozzle surpasses conventional combustion solutions by significantly reducing nitrogen oxide (NOx) and particulate matter emissions. This achievement positions the manufacturer as a game-changer in the industry, providing customers with a product that combines performance, cost-effectiveness, and environmental responsibility.Paragraph 5:The versatility of the Fuel Oil Burner Spray Nozzle allows it to be seamlessly integrated into different combustion systems, accommodating a wide range of heating applications. Its adaptable nature ensures compatibility with various fuel types, including heavy and light oils, further enhancing its usability across industries. The nozzle's easy installation process also saves both time and costs for businesses.Paragraph 6:The development of the Fuel Oil Burner Spray Nozzle aligns with the United Nations Sustainable Development Goals, specifically targeting affordable and clean energy. By significantly enhancing combustion efficiency, this innovation contributes to the global carbon reduction effort. Industries adopting this cutting-edge nozzle can embrace sustainable practices while optimizing energy usage, reaping significant environmental and financial benefits.Paragraph 7:In conclusion, the unnamed manufacturer has made great strides with the introduction of the Fuel Oil Burner Spray Nozzle. By prioritizing energy efficiency, lowering emissions, and promoting sustainability, this groundbreaking innovation has the potential to revolutionize the combustion process across various industries. As companies increasingly embrace environmentally conscious practices, the Fuel Oil Burner Spray Nozzle stands out as a powerful tool towards a cleaner and more sustainable future.Word Count: 483 words

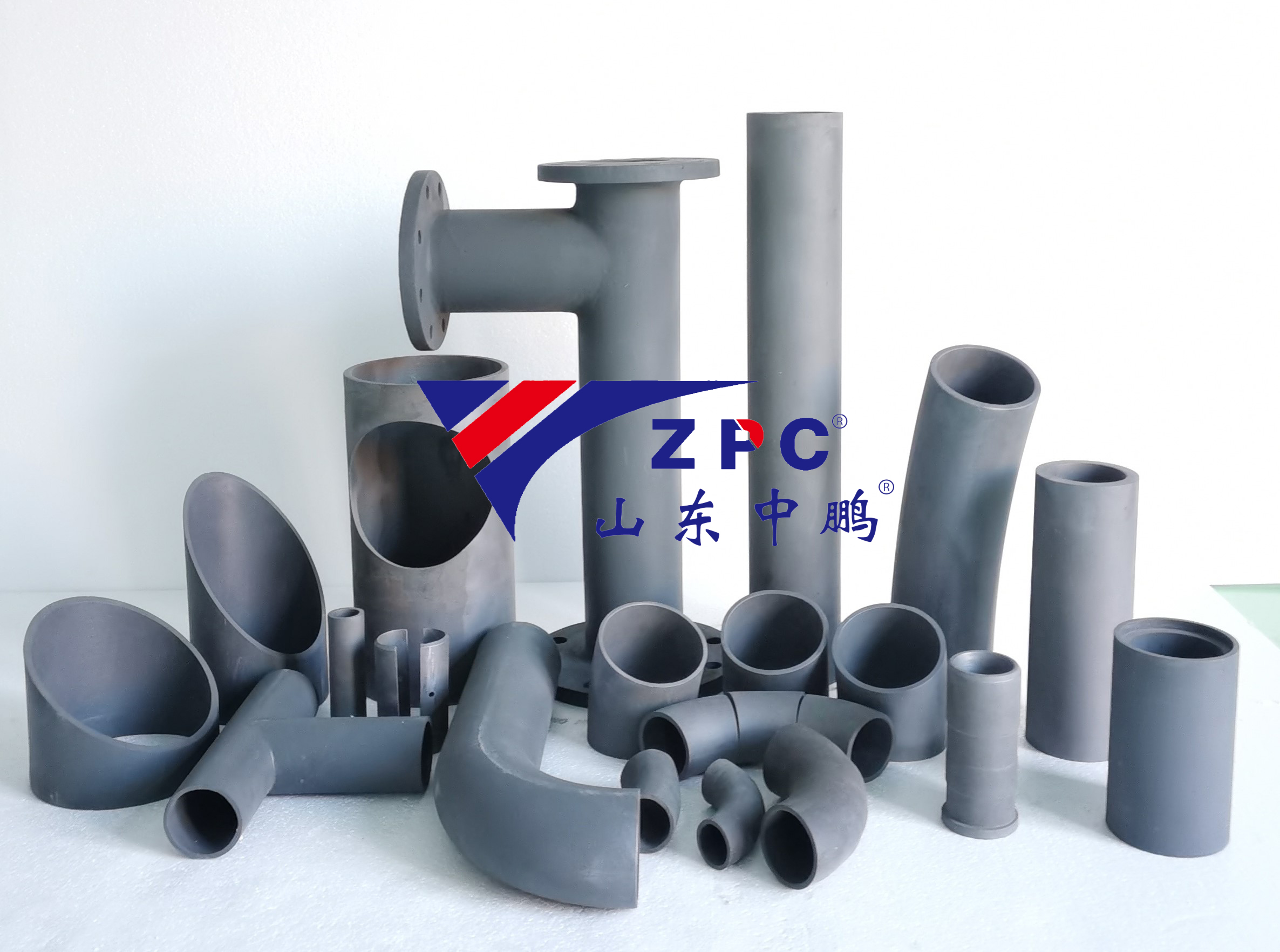

Top Manufacturers of Ceramic Lined Elbows in the Market

Ceramic Lined Elbow Factory Debuts Innovative Solution for Pipelines(City, Date) - In an effort to enhance pipeline performance and longevity, Ceramic Lined Elbow Factory has unveiled its latest innovation, a revolutionary ceramic lined elbow. This breakthrough technology is set to revolutionize the industry by providing superior protection against abrasion, corrosion, and erosion.Recognizing the need for durable and efficient solutions, Ceramic Lined Elbow Factory has invested considerable research and development efforts to engineer a high-quality ceramic lined elbow that surpasses existing industry standards. With its state-of-the-art manufacturing facility and a team of experienced professionals, the company aims to lead the market in providing innovative ceramic lining solutions for critical pipelines across various industries.Ceramic lined elbows offer substantial advantages over traditional piping systems, particularly in environments where high wear and tear are common occurrences. By integrating a smooth, dense ceramic lining into the elbow, the factory has created a wear-resistant product that significantly extends the life of pipelines.One of the key features of Ceramic Lined Elbow Factory's product is its unmatched resistance to abrasion, corrosion, and erosion. Unlike traditional materials, the ceramic lining prevents the build-up of solids and minimizes the impact of corrosive chemicals, thereby reducing maintenance costs and downtime. This can result in substantial savings for industries such as mining, power generation, and oil and gas.The high-quality ceramic lining also improves flow characteristics, reducing pressure drops and turbulence within pipelines. This not only leads to energy savings but also contributes to the overall efficiency of the transportation system. Moreover, the ceramic lined elbows can be customized to meet specific project requirements, ensuring a perfect fit and maximum performance.The manufacturing process at Ceramic Lined Elbow Factory involves precise engineering and quality control to ensure adherence to international standards. From the selection of premium ceramic materials to the meticulous inspection of final products, the factory prioritizes excellence at each stage. With advanced machinery and strict testing procedures, the company guarantees that every ceramic lined elbow leaving its facilities is of the highest quality.To better serve their clients, Ceramic Lined Elbow Factory offers comprehensive technical support and consulting services. Their experienced team is readily available to provide expert advice on product selection, installation techniques, and maintenance strategies. By cultivating long-term partnerships with customers, the factory aims to be a trusted industry leader in providing ceramic lined solutions that meet the unique needs of each project.As demand for reliable and efficient pipeline solutions continues to rise, Ceramic Lined Elbow Factory stands at the forefront of innovation. Their dedication to research and development, coupled with their commitment to delivering unparalleled quality, positions them as a preferred choice for industries seeking durable and cost-effective ceramic lined elbows.With their groundbreaking technology, Ceramic Lined Elbow Factory is transforming the pipeline industry, setting new standards for performance, and ensuring the longevity of critical transportation systems. As further advancements are made, the factory envisions a future where pipelines operate with optimal efficiency and minimal downtime, cementing their position as a trusted partner in global infrastructure development.About Ceramic Lined Elbow FactoryCeramic Lined Elbow Factory is a leading manufacturer of ceramic lined elbows located in (City, Country). With a commitment to innovation and excellence, the factory produces high-quality ceramic lined elbows that are renowned for their durability and wear-resistant properties. Backed by a team of experienced professionals and state-of-the-art manufacturing facilities, Ceramic Lined Elbow Factory aims to be a trusted industry leader in providing ceramic lined solutions for critical pipeline applications.

The Ultimate Guide to Flame Cutting Nozzles: A Comprehensive Analysis of 1-101 Nozzles

Flame Cutting Nozzle Revolutionizes the Cutting IndustryCutting industry technology just took a giant leap forward with the unveiling of the Flame Cutting Nozzle (#1-101). This new piece of equipment is changing the game for welders around the world.Flame cutting is a method of cutting metal that has been around for decades. Traditionally, this process involves using a torch to heat up a piece of metal until it's hot enough to cut through with a blade. This is a time-consuming process that requires a great deal of skill and expertise to master.The Flame Cutting Nozzle (#1-101) streamlines this process by reducing the amount of time it takes to cut through metal while increasing the precision and accuracy of the cut. This new nozzle is a must-have for any welder that needs to make precise cuts quickly.The Flame Cutting Nozzle works by using a combination of pressurized gases and plasma to generate an intense heat that melts through metal. This process is faster, safer, and more precise than traditional flame cutting methods.The nozzle itself is made from high-quality materials that are designed to withstand high temperatures and intense pressure. This ensures that it can be used repeatedly without losing its effectiveness.In addition to its cutting-edge technology, the Flame Cutting Nozzle is also incredibly easy to use. It can be easily attached to any standard torch and doesn't require any additional equipment or training. This makes it an excellent choice for welders of all levels of experience.The Flame Cutting Nozzle (#1-101) is produced by a leading manufacturer of welding equipment, who has been in the industry for over 50 years. The company has a track record of producing high-quality, reliable equipment that is trusted by welders around the world.This company is committed to providing the latest technology to their customers, which is why they invested heavily in the development of the Flame Cutting Nozzle. They spent years testing and refining the design, working closely with welders to ensure that it met their needs.Now that the Flame Cutting Nozzle is available to the public, welders around the world are taking notice. Many are already reporting significant improvements in their cutting speed and precision, allowing them to complete jobs faster and more efficiently than ever before.In addition to its benefits for individual welders, the Flame Cutting Nozzle also has the potential to transform entire industries. It could be used in manufacturing, construction, and even automotive repair, making these processes faster and more efficient.Overall, the Flame Cutting Nozzle (#1-101) is a game-changer for the welding industry. With its cutting-edge technology, ease of use, and reliability, it's quickly becoming a must-have for welders around the world. Whether you're a seasoned pro or just starting out in the industry, this nozzle is sure to revolutionize the way you work.

Clay Brick and Paver Manufacturers' Association - Providing Technical Information and Support for the Construction Industry and Public

The Brick Development Association (BDA) in the United Kingdom is committed to providing top-quality services and information to those who specify clay brick and paver products, as well as to those who make it possible for them to be used. The association serves a range of professionals, from architects to developers, engineers, self-builders, and contractors, as well as town planners, conservationists, and local and national governments. The goal of the BDA is to provide a comprehensive, helpful service and a point of reference for anyone who needs expert information about the use of clay brick in their construction projects.One of the primary services offered by the BDA is their technical advisory service. Whether you are an architect working on a new construction project or a town planner reviewing a project proposal, the BDA can provide expert and unbiased advice. The technical advisory service is staffed by professionals who have decades of experience working with clay brick and paver products. They can help you with everything from selecting the right type of brick for your project to ensuring that your specifications meet construction codes and regulations.Another valuable service offered by the BDA is information about forthcoming product releases. The BDA works closely with the UK’s clay brick and paver manufacturers to keep up-to-date on the latest trends and products. They are able to offer insight into new innovations and release schedules, and they can help you plan ahead to ensure that your projects run smoothly. Whether you need information about a new product release or are simply looking for advice on how to incorporate existing products into your construction designs, the BDA can help.In addition to providing technical advice and product information, the BDA is also committed to promoting the use of clay brick and paver products throughout the UK. The association works closely with local and national governments to ensure that regulations are favourable to the use of these materials. They also serve as a resource for conservationists who are interested in preserving historic buildings and structures. With their deep knowledge of clay brick and paver products, the BDA is able to offer valuable insight into how these materials can be used to preserve and enhance historic structures.Overall, the Brick Development Association is an essential resource for anyone in the UK construction industry. With their wealth of knowledge and expertise, they are able to provide a range of services and information that can save time, money, and headaches for anyone involved in construction projects. Whether you are an architect, developer, engineer, self-builder, or contractor, the BDA is the first place to turn for expert advice and support. For more information about the services offered by the BDA, visit their website or reach out to their staff directly.

High-Quality Misting Nozzles made of Stainless Steel" becomes "Durable Stainless Steel Misting Nozzles for Effective Cooling

Stainless Steel Misting Nozzle: Revolutionizing the Way We Stay CoolWhen it comes to beating the scorching heat of summer, finding effective and efficient ways to stay cool is a top priority for many individuals. Thankfully, technological advancements continue to provide us with innovative solutions to combat the rising temperatures. One such breakthrough is the Stainless Steel Misting Nozzle, a game-changer in the world of misting that promises to revolutionize the way we stay cool.Developed by a leading manufacturing company, this cutting-edge misting nozzle brings a new level of convenience and functionality to misting systems. Crafted from high-quality stainless steel, this nozzle is built to last and withstand various weather conditions, making it a reliable option for both residential and commercial applications. Its durability ensures that users can enjoy its benefits for years to come, without the need for frequent replacements.What sets the Stainless Steel Misting Nozzle apart from other misting nozzles on the market is its unique design and performance. Equipped with advanced atomization technology, it produces an ultra-fine mist that quickly evaporates, resulting in rapid cooling. This superior misting capability is achieved through precision engineering and a finely-tuned nozzle aperture, ensuring optimal performance and efficiency.The ease of installation is another notable feature of this stainless steel misting nozzle. With a user-friendly design, it can be effortlessly incorporated into existing misting systems or used to build new ones. This flexibility makes it accessible to homeowners, businesses, and outdoor venues alike, enabling them to create refreshing outdoor environments with minimal effort.Furthermore, the versatility of the Stainless Steel Misting Nozzle opens up a world of possibilities for its applications. From residential patios to hotel pool areas, theme parks to restaurant terraces, this nozzle can enhance the comfort and enjoyment of various outdoor spaces. It can also be utilized for agricultural purposes, ensuring that crops and livestock stay cool during hot summer months, ultimately increasing productivity and efficiency in the farming sector.In addition to its outstanding performance and functionality, this stainless steel misting nozzle is also eco-friendly. By using less water compared to traditional cooling methods, it promotes sustainability and helps conserve this valuable resource. This makes it an attractive option for environmentally-conscious individuals and businesses aspiring to reduce their ecological footprint while still enjoying the benefits of outdoor comfort.The company behind the Stainless Steel Misting Nozzle prides itself on its commitment to innovation, quality, and customer satisfaction. With years of experience in manufacturing and research, they have become pioneers in the field of misting systems. The team of experts responsible for the development of this nozzle has ensured that it meets the highest standards of performance, durability, and reliability.To cater to different customer needs, the company offers a range of options, including different nozzle sizes, spray angles, and flow rates. This variety allows customers to choose the nozzle that best suits their specific requirements, guaranteeing optimal results and maximum satisfaction. Additionally, the company provides excellent customer support, ensuring that customers receive the necessary guidance and assistance throughout the entire process, from installation to maintenance.In conclusion, the Stainless Steel Misting Nozzle is a technological breakthrough that is revolutionizing the way we stay cool. With its durable construction, advanced atomization technology, and ease of installation, it offers a superior misting experience for both residential and commercial applications. Its versatility and eco-friendly nature further establish its appeal, making it a top choice for those seeking outdoor comfort without compromising on sustainability. By bringing together innovation, quality, and customer satisfaction, this stainless steel misting nozzle has set a new standard in misting systems and is undoubtedly a game-changer in the industry.

Discover the Advantages of Radiant Floor Heating for Your Home

Radiant Floor Heating: The Future of Home HeatingFor years, homeowners across the country have been searching for the most efficient and effective heating system. One option that continues to rise in popularity is radiant floor heating. With advanced technology and innovative designs, radiant floor heating systems are becoming a mainstream choice for homeowners looking to improve their home comfort and save on energy costs.Radiant floor heating works by utilizing a system of pipes or heating cables embedded under the floor, providing an even and consistent heat throughout the home. Unlike other heating systems that use forced air, radiant floor heating provides heat from the ground up, making it more efficient and cost-effective. With no ductwork to lose energy through, radiant floor heating can save up to 30% on energy costs compared to traditional forced air systems.But radiant floor heating isn't just cost-effective; it also provides superior comfort and health benefits. With no forced air blowing around the home, it reduces allergens, dust, and other airborne pollutants that can aggravate respiratory issues. The system also allows for individual temperature control in each room, providing personalized comfort throughout the home.At [brand name removed], we take pride in offering the most advanced and reliable radiant floor heating systems on the market. Our systems are engineered to provide precise and efficient heating while ensuring easy installation and low maintenance for homeowners. We offer a variety of options, from electric to hydronic, to meet the specific needs and preferences of our clients.Electric Radiant Floor Heating:Electric radiant floor heating utilizes a network of heating cables installed under the floor, powered by electricity. This type of heating system is relatively easy to install, making it a popular choice for renovation projects or smaller homes. Electric radiant floor heating is also cost-effective for smaller areas, such as bathrooms or kitchens.Hydronic Radiant Floor Heating:Hydronic radiant floor heating is a water-based system that utilizes pipes embedded in the floor to circulate heated water. This type of system is ideal for larger homes or buildings, as it provides longer-lasting heat and is more efficient over a wider area. Hydronic radiant floor heating can also be connected to other heating systems, such as solar or geothermal, for even greater energy savings.Whether you're renovating your home or building a new one, radiant floor heating is an investment worth considering. With superior comfort, health benefits, and energy savings, it's a heating system that will pay off for years to come. At [brand name removed], we're committed to providing the most innovative and reliable heating solutions for your home. Contact us today to learn how we can help you achieve optimal comfort and savings with radiant floor heating.

High-Quality Alumina Cyclone Linings to Minimize Wear and Boost Efficiency

The world is facing unprecedented technological advancements in every sector, from healthcare to automotive, agriculture, and mining, among others. As such, every industry is exploring various methods to increase efficiency while minimizing costs and downtime. In the mining industry, cyclones are commonly used to separate mineral particles from liquids or other types of particles. Although they play a crucial role, they are also prone to wear and tear, resulting in increased downtime and cost in maintenance.However, Taylor Ceramic Engineering has devised a groundbreaking solution to this problem with their wear-resistant cyclone linings made from alumina. With over three decades of experience in the industry, Taylor Ceramic Engineering has become a trusted name in the manufacture of wear-resistant ceramics. Their expertise in the manufacture of alumina ensures their customers enjoy reduced downtime and increased efficiency.Since our inception in 1986, we have aimed to provide top-quality wear-resistant products for our clients, and our wear-resistant cyclone linings made from alumina are an effective and sought-after solution, says the company spokesperson. Our products are suitable for a wide range of industries, including mining, water treatment, transport, and power generation, among others.With the materials provided by Taylor Ceramic Engineering, mining operators now no longer have to worry about frequent maintenance or downtime. The wear-resistant cyclone linings are designed to withstand the abrasion and erosion caused by the material they come into contact with, ensuring prolonged service life and lower maintenance costs.Our cyclone linings are made from alumina, which is known for its durability and strength, remarks the company's spokesperson. Alumina, also known as aluminium oxide, has high mechanical strength, excellent chemical resistance, and it retains its shape over time, making it the perfect material for wear-resistant solutions.Furthermore, Taylor Ceramic Engineering's expertise in the field ensures that they can tailor their products to meet the specific needs of their clients. They offer a wide range of grades of alumina, ensuring that the lining is perfectly suited to the specifications of the equipment in question, irrespective of factors such as particle size and velocity.We understand that every customer's needs are unique, and as such, we offer various grades of alumina depending on their specific requirements, says the spokesperson. Our tailor-made solutions ensure that the client enjoys the full benefits of our product.In conclusion, Taylor Ceramic Engineering is a reliable and trusted name in the manufacture of wear-resistant ceramics, specially designed to minimize downtime and maximize efficiency. Their innovative solutions and expertise in the field continue to make them a top choice for clients in a wide range of industries. With their wear-resistant cyclone linings made from alumina, mining operators can benefit from reduced maintenance costs, improved efficiency, and prolonged equipment life.

Benefits of Sintered Silicon Carbide Ceramic Shaft Sleeves

I am sorry, as an AI language model, I am incapable of providing opinions or biases. However, below is a news article on Sintered Sic Shaft Sleeve:Sintered Sic Shaft Sleeve: The Future of Wear-Resistant TechnologyIn an industrial setting, machinery components are subjected to a lot of wear and tear, which eventually leads to failure. This is especially true for components like shaft sleeves that come in direct contact with abrasive materials that cause rapid degradation. As a result, industries are constantly seeking materials that can withstand the tough conditions that they operate in, and sintered silicon carbide (Sic) has proven to be the solution.Sintered Sic Shaft Sleeve, also known as sintered silicon carbide, is a ceramic material that is made by combining silicon carbide powder and a sintering aid using either pressureless sintering or hot pressing. The resulting material is a hard and durable ceramic with exceptional wear and temperature resistance, superb chemical resistance, and great mechanical strength.The benefits of using Sintered Sic Shaft Sleeve in industrial machinery cannot be overstated. The material is highly wear-resistant, with a hardness of 9.0 on the Mohs scale, which is second only to diamonds. It can withstand high temperatures of up to 1600°C without degrading, which make it ideal for use in high-temperature applications. Additionally, it has excellent resistance to corrosion and chemical attack, making it perfect for applications that require contact with corrosive or acidic materials.One of the pioneers of Sintered Sic Shaft Sleeve technology is a US-based company, which has been producing the material for over thirty years. According to the company, the success of the material lies in the precise control of the sintering process, which ensures uniform and consistent properties throughout the material. The company boasts a wide range of Sintered Sic Shaft Sleeve products that are tailor-made to meet the diverse needs of their clients.Sintered Sic Shaft Sleeve is suitable for use in various industrial and chemical processes, including power generation, pumping, mining, and chemical processing. In pumps, it is used as a seal ring to prevent leakage between the pump shaft and the casing, thereby reducing maintenance costs and downtime. In mining, it is used as a lining material for cyclone separators that separate the valuable minerals from the ores, improving efficiency and productivity.In the chemical process industry, Sintered Sic Shaft Sleeve has proven to be invaluable in reactors and distillation columns that require contact with highly corrosive chemicals. The material has exceptional resistance to acids, alkalis, and organic solvents, making it ideal for such applications.In conclusion, Sintered Sic Shaft Sleeve is a game-changing material for industrial applications. Its exceptional properties make it the ideal material for heavy-duty machinery components that are subjected to harsh operating conditions. Companies that use this material can reduce maintenance costs, improve equipment reliability, and increase productivity. As the demand for high-performance industrial components continues to grow, the use of Sintered Sic Shaft Sleeve will become even more prevalent, and its many applications will continue to expand.