Discover the Best High-Quality SSIC Products on the Market

By:Admin

In the world of advanced industrial applications, the demand for high-quality materials that can withstand extreme conditions and deliver exceptional performance has never been higher. In this scenario, {Company name}, a leading manufacturer of advanced ceramics and materials, has emerged as a top choice for businesses looking for reliable and innovative solutions.

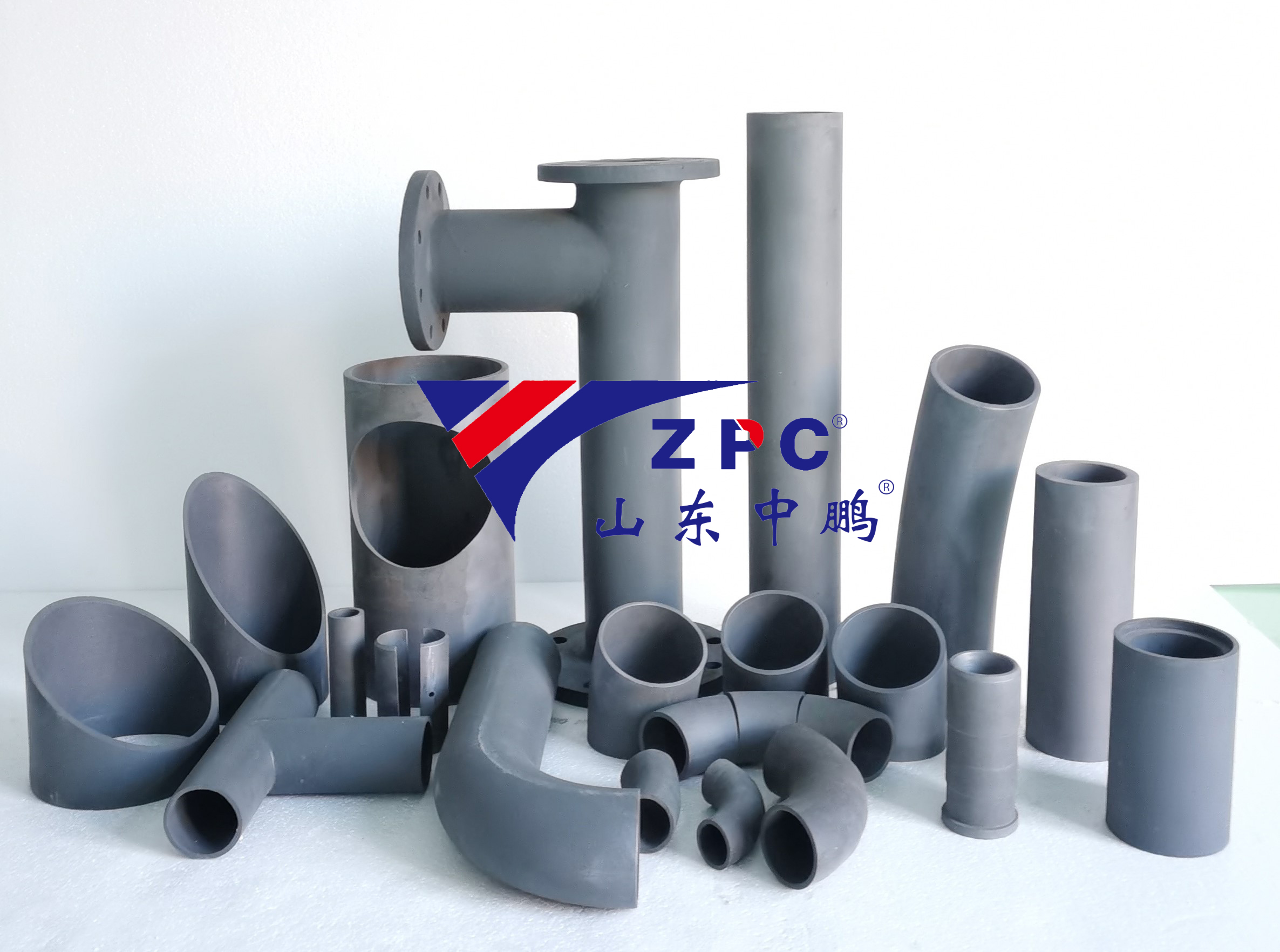

With its cutting-edge technology and relentless commitment to quality, {Company name} has been setting industry benchmarks in the production of advanced ceramics. One of the standout materials from their portfolio is high-quality Ssic (silicon carbide), a versatile and durable ceramic that is revolutionizing several industrial sectors.

Ssic is known for its exceptional hardness, high thermal conductivity, low thermal expansion, and excellent corrosion resistance. These unique properties make it an ideal material for a wide range of challenging applications, including advanced machinery, aerospace components, automotive parts, and semiconductor equipment.

{Company name} has leveraged its expertise and state-of-the-art manufacturing facilities to produce Ssic components that meet the stringent requirements of various industries. By working closely with their clients, the company is able to customize Ssic products to suit specific application needs, ensuring optimal performance and reliability.

Furthermore, {Company name}'s commitment to innovation is evident in its continuous research and development efforts to enhance the properties of Ssic. Through advanced material design and engineering, the company is constantly pushing the boundaries of what is possible with Ssic, opening up new opportunities for its use in cutting-edge technologies.

The exceptional quality of {Company name}'s Ssic has been widely recognized by industry experts and business partners. This has established the company as a trusted supplier of advanced ceramics to some of the most demanding sectors, including aerospace, defense, and industrial manufacturing.

In the aerospace industry, Ssic components have proven to be a game-changer, as they can withstand high temperatures, high mechanical loads, and aggressive environments. With the ever-increasing demands for lighter and more durable aircraft components, Ssic has become an indispensable material for the development of next-generation aerospace technologies.

The defense sector has also embraced Ssic for its superior performance under extreme conditions. Whether it's for armor solutions, ballistic protection, or military equipment, {Company name}'s Ssic has become the go-to material for meeting the stringent requirements of defense applications.

In addition to aerospace and defense, {Company name}'s Ssic has also found wide-ranging applications in industrial manufacturing. Its outstanding thermal conductivity and wear resistance have made it an essential material for high-temperature furnaces, pumps, and machinery used in the production of steel, chemicals, and other industrial products.

Moreover, {Company name} has been at the forefront of introducing Ssic to the rapidly evolving semiconductor industry. With the growing demand for high-performance processing technologies, the semiconductor sector has turned to Ssic for its exceptional heat dissipation properties and chemical inertness, critical for the efficient and reliable operation of semiconductor manufacturing equipment.

{Company name}'s Ssic has also made significant inroads into the automotive industry, where its high wear resistance and thermal conductivity make it an ideal material for engine components, brake systems, and other critical parts. With the automotive sector's increasing focus on efficiency and sustainability, Ssic's potential to enhance performance and durability is becoming increasingly valuable.

In conclusion, {Company name}'s high-quality Ssic is redefining the standards for advanced industrial applications. By delivering exceptional performance, reliability, and versatility, Ssic has become the material of choice for businesses looking to stay ahead in the rapidly evolving industrial landscape. As the company continues to innovate and expand its product offerings, the future looks bright for Ssic and the industries it serves.

Company News & Blog

Where to Find Top Quality Alumina Tiles: Your Ultimate Guide

release outlining the company's history, products, and achievements.Alumina Tile Supplier is a leading manufacturer of high-quality alumina tiles that are used in a wide variety of industrial applications, including mining, power generation, cement manufacturing, and steelmaking. With a history dating back more than a decade, the company has established itself as a trusted supplier of industrial ceramics across the globe.The company's roots can be traced back to the early 2000s, when a team of experienced ceramic engineers came together with the goal of developing innovative solutions for the toughest wear and corrosion problems in the industry. Using the latest technologies and manufacturing processes, they developed a range of alumina tiles that were tougher, more durable, and longer lasting than anything that had come before.Today, Alumina Tile Supplier is recognized as a world leader in the manufacture of high-quality ceramic wear-resistant products. The company offers a wide range of tiles in various shapes and sizes to meet the needs of different industries and applications. These include hexagonal tiles, square tiles, and ceramic cylinders, among others, all of which are designed to withstand high levels of wear and corrosion.One of the company's key strengths is its commitment to quality. Alumina Tile Supplier uses only the highest quality raw materials, such as premium grade alumina and zirconia ceramics, and employs strict quality control measures throughout the manufacturing process. This ensures that customers receive tiles that meet the highest standards of performance and durability.Over the years, Alumina Tile Supplier has developed a reputation for excellence in customer service as well. With a team of experienced professionals who are dedicated to meeting the needs of their customers, the company has earned the trust and loyalty of clients around the world. From initial consultations to installation and ongoing support, the company works closely with customers to ensure that they receive the best possible products and services.The list of industries and applications that Alumina Tile Supplier's products can be found in is extensive. Some of the most common uses include lining chutes, hoppers, cyclones, pipes, and other industrial equipment. Whether it's protecting mining equipment from abrasion, preventing corrosion in chemical processing plants, or reducing downtime in power plants, Alumina Tile Supplier's products are up to the challenge.Over the years, Alumina Tile Supplier has achieved a number of notable milestones in its quest for excellence. Some of the company's most significant achievements include:- Development of new wear-resistant formulations and manufacturing processes that have increased the durability and performance of its alumina tiles.- Expansion of its manufacturing facilities and distribution network to serve customers around the world.- Implementation of state-of-the-art manufacturing technology and quality control systems to ensure consistent product quality and performance.- Development of new applications for its products in industries ranging from mining and power generation to cement manufacturing and steelmaking.As Alumina Tile Supplier continues to grow and innovate, it remains committed to providing the highest quality products and services to its customers. With a team of skilled professionals and a dedication to excellence, the company is well positioned to meet the evolving needs of the industrial sector for years to come.

Exploring the Best Deals on CNC Plasma Cutters for Sale

CNC Plasma Cutting Machines: A Revolutionary Solution for Modern IndustriesIn our ever-evolving world of technology, industries are continuously searching for innovative solutions to enhance their efficiency and productivity. One such solution that has gained significant traction is the CNC plasma cutting machine. With numerous companies offering CNC plasma cutters for sale, the demand for this cutting-edge technology is on the rise.CNC plasma cutting machines have revolutionized the metal fabrication industry by providing a precise and efficient method for cutting a wide range of metals with speed and accuracy. These machines utilize plasma, an ionized gas consisting of positively charged ions and negatively charged electrons. When combined with a CNC (Computer Numerical Control) system, the result is a powerful and automated cutting process that allows for intricate designs and complex shapes.The main advantage of using a CNC plasma cutting machine is its incredible accuracy. These machines are equipped with advanced software that can precisely follow intricate cutting patterns. This level of precision ensures minimal material wastage, reducing costs and maximizing productivity. Moreover, by utilizing the CNC system, operators can easily replicate designs, leading to consistent results and better quality control.Another notable advantage of CNC plasma cutting machines is their quick turnaround time. Traditional cutting methods often required time-consuming manual labor, whereas CNC plasma cutting machines can swiftly and accurately cut through various thicknesses of metals. This speed enables businesses to meet tight deadlines and increases overall productivity.Furthermore, CNC plasma cutting machines offer flexibility and versatility. These machines are capable of cutting a wide range of metals, including steel, aluminum, brass, and copper. This versatility allows businesses from various industries, such as automotive, aerospace, and construction, to utilize one machine for multiple purposes, thus eliminating the need for separate cutting equipment and reducing costs.The safety features incorporated within CNC plasma cutting machines cannot be ignored. These machines are equipped with automatic height control systems, which guarantee operator safety by maintaining a consistent standoff distance between the torch and the metal being cut. Additionally, the modern design of these machines ensures minimal emissions and reduces the risk of accidents in the workplace.Company IntroductionAs one of the leading providers of CNC plasma cutters in the industry, our company has established a reputation for delivering high-quality and reliable machines to businesses across various sectors. With years of experience, we have honed our expertise in manufacturing cutting-edge technology while ensuring customer satisfaction.Our CNC plasma cutting machines incorporate the latest advancements in software and hardware, allowing for seamless integration and exceptional performance. We prioritize quality control at every step of the manufacturing process, ensuring that each machine leaving our facility is built to last and deliver consistent results.In addition to our commitment to quality, we understand the importance of excellent customer service. Our dedicated team of professionals is always available to assist with installation, training, and ongoing support. We believe in building long-term relationships with our customers and are constantly striving to exceed their expectations.With a wide range of CNC plasma cutters for sale, we offer machines suitable for businesses of all sizes and requirements. Whether you need a compact machine for a small workshop or a large-scale industrial solution, we have you covered. Our machines are priced competitively, allowing businesses to enhance their efficiency without compromising their budget.In conclusion, CNC plasma cutting machines have revolutionized metal fabrication by offering precision, speed, and versatility. Businesses from various industries are embracing this technology to increase productivity, reduce costs, and enhance their overall efficiency. With our company's dedication to quality and customer service, we are proud to be at the forefront of providing high-performance CNC plasma cutters for sale, helping businesses navigate the demands of modern industries.

High quality RBSiC (SiSiC) Burner Nozzle for industrial applications

RBSiC (SiSiC) Burner Nozzle: The Future of High-Temperature Industrial ProcessesIn today's rapidly evolving industrial landscape, companies are constantly seeking innovative solutions to enhance their manufacturing processes. One such solution that has been making waves in the industry is the RBSiC (SiSiC) Burner Nozzle, a cutting-edge technology that is revolutionizing high-temperature industrial processes.The RBSiC (SiSiC) Burner Nozzle is the brainchild of a leading materials technology company, which has been at the forefront of developing advanced ceramics and refractory products for a wide range of industrial applications. With a strong focus on research and development, the company has continuously pushed the boundaries of materials science to create products that offer superior performance, durability, and efficiency.The RBSiC (SiSiC) Burner Nozzle is a testament to the company's commitment to innovation and excellence. It is designed to withstand extreme temperatures and harsh operating conditions, making it an ideal choice for a variety of high-temperature industrial processes such as metal smelting, chemical processing, and incineration. The unique properties of RBSiC (SiSiC) material, including high thermal conductivity, excellent thermal shock resistance, and exceptional corrosion resistance, make it a game-changer in the industry.One of the key advantages of the RBSiC (SiSiC) Burner Nozzle is its ability to deliver precise and efficient heat distribution, resulting in significant energy savings and reduced emissions. This is particularly important in today's environmentally conscious world, where industries are under increasing pressure to minimize their carbon footprint and adopt sustainable practices. By utilizing the RBSiC (SiSiC) Burner Nozzle, companies can not only improve their operational efficiency but also contribute to a cleaner and greener environment.Furthermore, the RBSiC (SiSiC) Burner Nozzle offers extended service life and minimal maintenance requirements, thereby reducing downtime and operational costs for industrial facilities. Its robust construction and reliable performance make it an invaluable asset for businesses looking to enhance their productivity and competitiveness in the market.In addition to its technological prowess, the company behind the RBSiC (SiSiC) Burner Nozzle is also known for its dedication to customer satisfaction. It provides comprehensive technical support and customized solutions to meet the specific needs of its clients. Through close collaboration with industrial partners, the company ensures that the RBSiC (SiSiC) Burner Nozzle is seamlessly integrated into existing systems, maximizing its potential and delivering tangible benefits to end-users.Looking ahead, the future of high-temperature industrial processes seems promising with the RBSiC (SiSiC) Burner Nozzle leading the way. As industries continue to evolve and demand high-performance solutions, this pioneering technology is expected to play a pivotal role in shaping the manufacturing landscape, setting new standards for efficiency, reliability, and sustainability.In conclusion, the RBSiC (SiSiC) Burner Nozzle represents a significant advancement in materials technology, offering unparalleled performance and versatility for high-temperature industrial processes. With its innovative design, superior properties, and the backing of a reputable company, it has the potential to transform the way industries operate, paving the way for a more efficient and sustainable future. As companies embrace this cutting-edge technology, they can look forward to reaping the rewards of enhanced productivity, reduced environmental impact, and long-term success in the global market.

Durable Tiles: Discover Top Picks for Wear Resistant Flooring

Wear Resistant Tiles Revolutionize Industry SolutionsWear and tear are inevitable in industries that demand high levels of abrasion. It is a recurring problem that can lead to frequent equipment repair or replacement costs, significant downtime, and loss of productivity. But with the availability of wear-resistant tiles, these concerns can be minimized, if not eliminated.Wear-resistant tiles are ceramic or rubber tiles that are specifically designed to withstand high levels of abrasion and impact. These tiles are installed as liners, coatings, or coverings to protect equipment surfaces such as chutes, silos, hoppers, and conveyors. With their superior wear and impact resistance properties, these tiles are a cost-effective solution to enhance the lifespan of equipment surfaces and reduce maintenance downtime.One company that offers a complete range of wear-resistant tile solutions is (company name). With over (number) years of experience in the ceramic tiling industry, (company name) is one of the most trusted names in wear-resistant tiles. The company's wear-resistant tiles are manufactured with state-of-the-art technology, ensuring that they meet the highest standards of quality and durability.At (company name), customers can choose from a wide range of wear-resistant tile solutions that best fit their specific requirements. The company's ceramic wear-resistant tiles are made from high-purity alumina ceramics, which offer excellent wear and heat resistance properties. These tiles are perfect for applications that involve high temperatures, corrosive media, and heavy impact.The company also offers a range of rubber wear-resistant tiles that are ideal for impact and wear resistance in applications such as mining, cement, and power plants. These tiles are made from a blend of natural and synthetic rubber, which provides excellent anti-abrasion properties while remaining flexible to accommodate a wide range of surface profiles.(Company name) also offers custom-made wear-resistant tile solutions to meet the unique needs and demands of their clients. The company's team of highly skilled engineers and technicians work closely with clients to design and manufacture customized tiles that offer superior performance and longer service life than standard tiles.Aside from their high-quality products, what sets (company name) apart from their competitors is their commitment to providing exceptional customer support. The company offers comprehensive technical support and assistance, from the initial consultation and design stage to the final installation and maintenance of the tiles. They also offer on-site installation and training programs to ensure that clients can fully maximize the benefits of their wear-resistant tile solutions.With their exceptional product quality, customer support, and value for money, it's no surprise that (company name) has become the go-to partner of choice for businesses across various industries. The company has successfully served clients from all over the world, providing them with efficient, reliable, and durable solutions that have helped them improve their business operations and bottom line.In summary, wear-resistant tiles are a game-changer for businesses that require equipment surfaces to withstand high levels of abrasion and impact. With (company name)'s wide range of exceptional wear-resistant tile solutions, clients can enjoy longer service life, reduced maintenance costs, and increased productivity. Coupled with their world-class customer support, (company name) is a company that businesses can rely on to provide them with top-quality wear-resistant tile solutions that best meet their needs.

Affordable Radiant Heating Systems for Your Home - Floor, Baseboard, Geothermal and Solar Thermal Options Available

For homeowners looking to keep their homes warm and comfortable throughout the year, radiant floor heating is an affordable and efficient solution. At Argent Heating & Cooling, we offer a range of radiant heating options to meet the unique needs of each of our customers. Whether you're looking for radiant floor heating, baseboard heating, geothermal heating, or solar thermal heating systems, our team of certified heating technicians has the expertise and experience to get the job done right.Radiant floor heating is an increasingly popular heating option for homeowners. This system uses a series of plastic tubes or electrical heating elements to radiate warmth evenly throughout the home, starting from the floor up. This type of heating system is particularly well-suited for colder climates, where warm floors can make a huge difference in overall comfort levels.One of the biggest benefits of radiant floor heating is that it is both energy-efficient and cost-effective. Unlike traditional forced-air heating systems, radiant floor heating is able to operate at lower temperatures while still keeping your home warm and comfortable. This means that not only will you save money on your energy bills, but you'll also be doing your part to help reduce your carbon footprint.Another advantage of radiant floor heating is that it is very versatile. Whether you're building a new home or renovating an existing one, there are a variety of different types of radiant floor heating systems available to suit your needs. From electric systems that are easy to install in existing homes to hydronic systems that are perfect for new construction, our team of heating experts can help you choose the right system for your home.In addition to radiant floor heating, we also offer a range of other heating options, including baseboard heating, geothermal heating, and solar thermal heating systems. Baseboard heating uses electric or hot water heaters to distribute heat throughout the home, while geothermal heating uses the earth's natural heat to keep your home comfortable all year long. Solar thermal heating utilizes the sun's energy to heat water or air, which is then circulated throughout the home. Each of these systems has its own unique benefits, and we can help you choose the one that's right for you.At Argent Heating & Cooling, we're committed to providing our customers with the very best in heating and cooling solutions. Whether you're looking for radiant floor heating, baseboard heating, geothermal heating, or solar thermal heating systems, we've got you covered. With our team of certified heating technicians and our commitment to quality workmanship and customer service, you can rest assured that your heating system will be installed and maintained to the highest standards. Contact us today to learn more about our heating services and how we can help keep your home warm and comfortable all year long.

Rugged and Durable Silicon Carbide Products: Beams, Plates, Rollers, and More by IPS Ceramics

Silicon Carbide Rollers: The Rugged and Dependable PerformerWhen it comes to high-temperature applications, the choice of materials for manufacturing various components becomes critical. Silicon Carbide (SiC) is a popular material of choice due to its excellent properties and performance in high-temperature environments. Silicon Carbide Rollers are one such application where the material's superior properties and performance make them rugged and dependable performers for many industrial processes.IPS Ceramics offers various types of Silicon Carbide products, including beams, batts, plates, and rollers, specifically designed to cater to different application requirements. The use of Silicon Carbide has become increasingly prevalent in recent years, owing to its exceptional thermal properties, high strength, and resistance to wear and chemical corrosion.The Silicon Carbide Rollers' unique properties make them ideal for use in heat-treatment processes and kiln firing applications, where temperatures may exceed 1500 ℃. The rollers' ability to withstand high temperatures without bending or warping makes them an invaluable component in industrial processes. Silicon Carbide Rollers are impervious to chemical attacks and provide reliable support to the products being processed, ensuring the consistent and uniform heating and cooling of products that are essential to many industries.The high strength and wear resistance of Silicon Carbide Rollers make them durable and minimize the need for frequent replacements. These properties reduce production downtimes and costs and increase overall efficiency, making them a popular choice among manufacturers.IPS Ceramics offers Silicon Carbide Rollers in various dimensions, shapes, and specifications, making them adaptable to different requirements. Our team of experts has experience in designing and manufacturing Silicon Carbide Rollers that cater to specific industrial processes' needs.The use of Silicon Carbide Rollers is not limited to heat-treatment processes alone. They are also widely used in glass manufacturing, steel production, and various thermal processing applications. Their robustness, high thermal conductivity, and low thermal expansion make them ideal for use in these applications, ensuring that products remain stable throughout the manufacturing process.To conclude, the Silicon Carbide Rollers' rugged and dependable performance make them an invaluable component in many industrial processes. Their superior properties make them the material of choice for manufacturers looking for longevity, reliability, and performance from their equipment. IPS Ceramics provides a wide range of Silicon Carbide Rollers that meet the specific needs of various industrial applications. With our expertise, we can assist manufacturers in selecting the right Silicon Carbide Rollers for their manufacturing processes. For all your Silicon Carbide Roller requirements, contact IPS Ceramics today!

Revolutionizing Industries: Harnessing the Power of Silicon Carbide Micropowder

Silicon carbide micropowder, a high-performance material with excellent thermal and mechanical properties, has become increasingly popular in various industries. One of the manufacturers of silicon carbide micropowder, based in China, has been producing high-quality products for more than 20 years.The company specializes in the production of silicon carbide micropowder and other related materials. It uses advanced technology and state-of-the-art equipment to produce high-purity, high-density silicon carbide micropowder. The company guarantees that its products meet the international standards of quality, safety, and performance.Silicon carbide micropowder can be used in different industries, such as aerospace, defense, automotive, and electronics. It has excellent thermal conductivity, high hardness, low coefficient of thermal expansion, and corrosion resistance. Silicon carbide micropowder is used to make cutting tools, wear-resistant parts, thermocouples, and high-temperature semiconductors.Silicon carbide micropowder is also used in metal matrix composites. Metal matrix composites are materials made by partially melting and blending metals with other materials such as silicon carbide micropowder. These composites have excellent mechanical properties and can be used in aerospace, defense, and automotive industries.The company's silicon carbide micropowder is made from high-purity silicon carbide raw materials. The raw materials are carefully selected and analyzed to ensure that they meet the company's standards of quality. The silicon carbide micropowder produced by the company has a high purity level of up to 99.99%, which is ideal for high-tech applications.The company has a well-established quality control system that ensures consistent quality in all its products. The company follows strict quality standards throughout the manufacturing process. From raw material testing to final product inspection, every step of the process is monitored and controlled to ensure the highest quality product.The company also offers customized solutions to meet the specific needs of its customers. The company's technical team works closely with customers to develop customized solutions that meet their unique requirements. This approach has helped the company to become a trusted partner of many leading companies in different industries.The company has a strong commitment to environmental sustainability. It uses environmentally friendly production processes and technologies that minimize waste and reduce emissions. The company also follows the principles of the circular economy by recycling and repurposing materials.In conclusion, the company is a leading manufacturer of high-quality silicon carbide micropowder. Its commitment to quality, customer satisfaction, and environmental sustainability has made it a trusted partner in various industries. With its advanced technology, state-of-the-art equipment, and experienced staff, the company is well-positioned to meet the growing demand for silicon carbide micropowder around the world.

Two Contract Workers Suffer Severe Burns After Liquid Metal Spill at Steel Plant in Visakhapatnam

Working in a steel plant can be a challenging task as it involves handling heavy machinery and hazardous materials. One such incident happened recently where two contract workers suffered severe burns due to liquid metal spillage. The incident occurred in the SMS unit of a steel plant in Visakhapatnam.It is reported that the workers were performing their duties when suddenly liquid metal spilled on them. While some workers escaped with minor injuries, two workers sustained severe burns. The cause of the accident was the failure of the burner nozzle. When the nozzle failed, it caused a leakage of liquid metal, which resulted in the accident.Burner nozzles are essential components in steel plants as they help in the production of hot and molten metals. They are used to inject fuel and air into the furnace to generate high temperatures. If the burner nozzle is not functioning correctly or has any faults, it can lead to accidents such as the one that occurred in this steel plant.Steel plants are known for their high-risk working environments, and accidents are common. However, companies can take measures to reduce the risk of such accidents. Proper training should be provided to all workers involved in handling machinery and hazardous materials. Workers should be equipped with the necessary safety gear such as helmets, gloves, and protective clothing.Regular maintenance and inspection of machinery and equipment should be carried out to ensure their proper functioning. This can prevent accidents caused by faulty machinery. It is also essential to create a culture of safety in the workplace, where workers are encouraged to report any hazards or faults in machinery.In conclusion, accidents can happen in any workplace, but they can be avoided by taking proper safety measures. The incident in the steel plant in Visakhapatnam highlights the importance of ensuring the proper functioning of machinery and equipment in high-risk environments. Burner nozzles play a crucial role in steel plants, and their maintenance and inspection are necessary to prevent accidents. By implementing safety measures, companies can provide a safer working environment for their employees, reducing the risk of accidents.

Electric Room Heaters: How They Affect Your Energy Bill and Which Ones Are the Best for Non-Industrial Spaces

Comparing LPG and Natural Gas Jet Nozzles: Which is More Efficient?

Title: Leading Energy Solutions Provider Introduces Next-Generation Jet Nozzle for LPG or NGIntroduction:In a groundbreaking development, a renowned energy solutions provider has unveiled its latest innovation in the form of a cutting-edge jet nozzle designed for use with Liquefied Petroleum Gas (LPG) or Natural Gas (NG) fuels. This exceptional company, with a diverse portfolio of high-performance products, has once again shown its commitment to revolutionizing the energy industry with its state-of-the-art technology. The newly introduced LPG or NG jet nozzle promises enhanced performance and efficiency, contributing to a cleaner and more sustainable future.Body:1. Introduction to the Company:With a rich history spanning over several decades, the company has solidified its position as a key player in the energy sector. Renowned for its unwavering dedication to research, development, and innovation, the company embodies excellence and serves customers across numerous industries globally. Their wide range of products guarantees optimal performance, efficiency, and environmental sustainability.2. The Need for Advanced Jet Nozzles:As the demand for cleaner and more efficient fuel sources continues to rise, so does the importance of developing advanced jet nozzles to ensure optimized combustion. LPG and NG have gained popularity due to their lower carbon emissions and cost-effectiveness. The introduction of an innovative jet nozzle specifically tailored for these fuels fills a critical gap in the market.3. Cutting-Edge Design and Functionality:The newly unveiled LPG or NG jet nozzle boasts a meticulously crafted design, incorporating state-of-the-art features that enhance fuel atomization, combustion efficiency, and overall performance. Its robust construction ensures durability, even under demanding operating conditions. The nozzle's advanced design guarantees a stable and consistent fuel-air mixture, facilitating maximum combustion efficiency and minimizing pollutant emissions.4. Enhanced Performance and Efficiency:This next-generation jet nozzle is engineered to deliver unparalleled performance, resulting in improved energy efficiency and reduced fuel consumption. By ensuring precise fuel atomization, the nozzle optimizes combustion, minimizing wastage and maximizing thermal efficiency. The innovative design also promotes cleaner combustion, leading to lower emissions of greenhouse gases and air pollutants.5. Versatility and Adaptability:A notable advantage of the LPG or NG jet nozzle is its outstanding versatility and adaptability, making it compatible with a wide range of applications. From industrial heating systems to residential cooking appliances, this nozzle's design allows for seamless integration across various equipment, meeting the diverse needs of end-users.6. Environmental Sustainability:As the world strives to combat climate change and reduce carbon footprints, the introduction of the LPG or NG jet nozzle is a significant step towards a greener future. By promoting efficient combustion and reducing emissions, this advanced nozzle aligns perfectly with global sustainability goals. Its adoption can contribute to improved air quality and a healthier environment.7. Industry Applications and Economic Benefits:Industries like automotive, heating, cooking, and power generation can benefit immensely from the cutting-edge LPG or NG jet nozzle. This technology empowers businesses to meet stringent environmental regulations while enjoying increased operational efficiency and reduced fuel expenditures. By combining sustainability and cost-effectiveness, this nozzle presents an attractive solution to organizations seeking enhanced performance and economic benefits.Conclusion:With the launch of their groundbreaking LPG or NG jet nozzle, this leading energy solutions provider once again demonstrates its unwavering commitment to technological innovation and sustainable practices. The advanced design, efficiency, and versatility of the nozzle position it as a game-changer in the energy industry. By facilitating cleaner combustion and reducing emissions, this next-generation jet nozzle paves the way for a greener and more sustainable future.