Quality Brass Burner Nozzle for Efficient Heating: Where to Buy

By:Admin

Founded in [year], Brass Burner Nozzle has continually focused on delivering cutting-edge technologies and superior products to meet the evolving needs of the industrial market. The company's dedication to innovation and excellence has earned them a strong reputation as a leading supplier of burner nozzles and related products.

Brass Burner Nozzle's extensive product line includes a wide range of burner nozzles, gas burners, and related accessories designed to provide reliable and efficient performance in a variety of industrial applications. Whether for heating, melting, or other industrial processes, Brass Burner Nozzle's products are engineered to deliver exceptional results and long-lasting durability.

One of the company's key strengths lies in its commitment to research and development. Brass Burner Nozzle continually invests in new technologies and engineering advancements to stay ahead of industry trends and offer innovative solutions to its customers. This dedication to innovation has allowed the company to introduce a series of new products that have set new standards for performance and efficiency in the industrial burner and heating sector.

In addition to its focus on product development, Brass Burner Nozzle is also dedicated to offering exceptional customer service and support. The company works closely with its clients to understand their specific needs and provide customized solutions that meet their unique requirements. Whether through product customization, technical support, or ongoing maintenance, Brass Burner Nozzle is committed to ensuring the success of its customers.

Furthermore, Brass Burner Nozzle is dedicated to sustainability and environmental responsibility. The company's products are designed to maximize energy efficiency and minimize environmental impact, helping businesses reduce their carbon footprint and contribute to a more sustainable future. By integrating environmentally friendly practices into its operations, Brass Burner Nozzle is aligning itself with the growing demand for eco-conscious solutions in the industrial sector.

With a global presence and a strong network of distributors and partners, Brass Burner Nozzle has established itself as a reliable and trusted supplier to industries around the world. The company's commitment to quality, innovation, and customer satisfaction has earned it the trust and loyalty of businesses in diverse sectors, from manufacturing to agriculture to energy production.

Looking ahead, Brass Burner Nozzle is poised to continue its trajectory of growth and success, driven by its relentless pursuit of excellence and its dedication to meeting the evolving needs of the industrial market. The company's ongoing investment in research and development, coupled with its focus on customer service and environmental responsibility, positions it for continued leadership in the industrial burner and heating sector.

Brass Burner Nozzle's expansion of its product line and its commitment to delivering exceptional solutions underscore its position as a leading force in the industrial market. As businesses worldwide seek innovative, reliable, and sustainable solutions for their industrial applications, Brass Burner Nozzle stands ready to meet their needs and exceed their expectations.

Company News & Blog

Luxury Watch Company Announces New Product Line

Lance: A Leader in the Snack IndustryLance is a renowned name in the snack industry, dedicated to providing consumers with delicious and high-quality snacks. The company has a long history of producing a wide variety of snacks, including crackers, cookies, and nuts. With a commitment to innovation and excellence, Lance has become a leader in the industry, offering products that are loved by people of all ages.Founded in 1913, Lance has a rich heritage that spans over a century. The company's commitment to quality and taste has made it a household name, with its products being enjoyed by millions of people across the country. Lance's dedication to using only the finest ingredients and the latest production techniques has helped it maintain its position as a leading snack manufacturer.In recent years, Lance has expanded its product offerings to cater to changing consumer preferences. The company has introduced new flavors and varieties of its popular products, as well as innovative packaging options that make it easier for people to enjoy their favorite snacks on the go. Lance's ability to adapt to the ever-changing market has solidified its position as a frontrunner in the snack industry.One of Lance's most notable achievements is its commitment to sustainability and social responsibility. The company has implemented several initiatives to reduce its environmental impact, such as using sustainable packaging materials and reducing energy consumption in its production facilities. Additionally, Lance is dedicated to giving back to the communities in which it operates, through various philanthropic efforts and partnerships with local organizations.Despite its long history and success, Lance continues to push the boundaries of snack innovation. The company's research and development team is constantly exploring new ingredients and flavor combinations to create products that are not only delicious but also nutritionally sound. Lance has also embraced the growing trend of healthier snacking options, offering a range of snacks that are low in calories and high in protein and fiber.The latest news from Lance revolves around its partnership with a leading retailer to launch a new line of snack products. This collaboration aims to bring a fresh take on snacking, with a focus on unique flavor profiles and convenient packaging. The new range of products is set to hit store shelves nationwide in the coming months, and consumers can expect a variety of exciting options to satisfy their snack cravings.In addition to this new product launch, Lance has also announced its plans to invest in new state-of-the-art manufacturing facilities to meet the increasing demand for its products. By expanding its production capacity, Lance aims to ensure that its snacks remain readily available to consumers while upholding the highest standards of quality and freshness.Moreover, Lance is dedicated to staying ahead of the curve in terms of consumer preferences and market trends. The company regularly conducts market research and gathers feedback from consumers to understand their evolving needs and desires. This information is then used to inform product development and marketing strategies, ensuring that Lance's snacks remain relevant and appealing to consumers.Looking ahead, Lance is poised to continue its legacy of excellence and innovation in the snack industry. With a steadfast commitment to quality, sustainability, and consumer satisfaction, the company is well-positioned to maintain its status as a leader in the market. As Lance continues to evolve and adapt to changing consumer preferences, consumers can expect to see an exciting array of new and improved snack products that deliver on taste, quality, and convenience.

High-Quality Heating Element Radiant Tube for Efficient Heat Transfer

Heating Element Radiant Tube Combines Efficiency and InnovationHeating Element Radiant Tube, a leading manufacturer of advanced heating solutions, is dedicated to providing high-quality products and cutting-edge technology to meet the needs of industrial and commercial customers. The company has gained a reputation for its commitment to innovation and customer satisfaction, and its latest product, the Radiant Tube, is a testament to that.The Radiant Tube is an advanced heating element that combines efficiency and innovation to deliver superior performance in industrial heating applications. It is designed to provide uniform and consistent heat distribution, resulting in improved process efficiency and reduced energy consumption. The Radiant Tube is engineered to withstand high temperatures and harsh operating conditions, making it ideal for a wide range of industrial applications, including heat treatment processes, annealing, and forging.One of the key features of the Radiant Tube is its advanced design, which maximizes heat transfer and minimizes heat loss. This unique design helps improve the overall efficiency of the heating process, resulting in cost savings for customers. Additionally, the Radiant Tube is constructed using high-quality materials that are resistant to corrosion and wear, ensuring long-term durability and reliability.In addition to its advanced design, the Radiant Tube is also equipped with the latest technology to enhance its performance. It is compatible with digital control systems, allowing for precise temperature control and real-time monitoring of the heating process. This advanced technology enables customers to optimize their heating processes and maintain consistent product quality.Furthermore, Heating Element Radiant Tube is committed to sustainability and environmental responsibility. The Radiant Tube is designed to minimize environmental impact by reducing energy consumption and emissions, helping customers meet their sustainability goals.With a strong focus on customer satisfaction, Heating Element Radiant Tube provides comprehensive support and service to its customers. The company's team of experts works closely with customers to understand their specific heating requirements and provide customized solutions to meet their needs. From initial consultation to installation and ongoing support, Heating Element Radiant Tube is dedicated to ensuring the success of its customers' heating processes.As a global leader in heating solutions, Heating Element Radiant Tube has a strong presence in the industrial and commercial heating market. The company serves a wide range of industries, including automotive, aerospace, steel, and glass manufacturing, providing reliable and efficient heating solutions to meet the diverse needs of its customers.In conclusion, the Radiant Tube is a cutting-edge heating element that offers superior performance, efficiency, and innovation. With its advanced design, state-of-the-art technology, and commitment to sustainability, Heating Element Radiant Tube is setting new standards in the industrial heating industry. Whether for heat treatment processes, annealing, or forging, the Radiant Tube provides a reliable and efficient heating solution for a wide range of applications. As Heating Element Radiant Tube continues to innovate and advance its heating solutions, it remains a trusted partner for industrial and commercial customers worldwide.

Effective Chemical Spraying Nozzle for Improved Coverage and Precision

Chemicals Spraying Nozzle Offers Innovative Solutions for Industry UseChemicals Spraying Nozzle (CSN) is a leading provider of innovative spraying solutions for a wide range of industries, including agriculture, manufacturing, and maintenance. The company prides itself on its commitment to providing high-quality products that meet the needs of its customers while also promoting environmental sustainability and worker safety.Founded in 1995, CSN has become a trusted name in the industry, known for its dedication to research and development, as well as its focus on customer satisfaction. The company's team of engineers and scientists work tirelessly to design and produce spraying nozzles that are not only effective and efficient but also environmentally friendly.CSN's spraying nozzles are designed to meet the specific needs of its customers, with a wide range of options available to accommodate different spraying applications. Whether it's for agricultural pest control, industrial coating, or surface cleaning, CSN has a nozzle to fit the job.One of the key features of CSN's spraying nozzles is their ability to provide a consistent and uniform spray pattern, ensuring that the chemicals are applied evenly and effectively. This not only helps to improve the efficiency of the spraying process but also minimizes chemical waste and reduces the environmental impact.In addition to their performance, CSN's spraying nozzles are also designed with worker safety in mind. By reducing the risk of chemical exposure and ensuring the proper application of chemicals, these nozzles help to create a safer working environment for employees.Furthermore, CSN is committed to sustainability and environmental responsibility. The company continuously invests in research and development to improve the efficiency of its spraying nozzles, reduce the use of harmful chemicals, and minimize the environmental impact of its products. This dedication to sustainability has earned CSN a reputation as a responsible and ethical provider of spraying solutions.One of CSN's most recent innovations is the development of a new line of spraying nozzles that are specifically designed for use in organic farming. These nozzles are engineered to minimize the use of synthetic chemicals, while still providing effective pest control and crop protection. This innovative approach has been well-received by organic farmers, who are increasingly turning to CSN for their spraying needs.In addition to its focus on agricultural applications, CSN also provides spraying solutions for other industries, including manufacturing and maintenance. From the application of coatings and lubricants to the cleaning and sanitization of industrial equipment, CSN's spraying nozzles are versatile and effective in meeting the diverse needs of its customers.As the demand for innovative spraying solutions continues to grow, CSN is well-positioned to meet the needs of its customers. With a strong commitment to research and development, a focus on customer satisfaction, and a dedication to sustainability, CSN is a leader in providing high-quality spraying nozzles for a wide range of industries.In conclusion, Chemicals Spraying Nozzle (CSN) is a trusted provider of innovative spraying solutions, with a focus on performance, worker safety, and environmental responsibility. With a strong reputation for quality and a dedication to meeting the diverse needs of its customers, CSN is well-positioned to continue leading the industry in providing high-quality spraying nozzles.

Advanced Radiation Pipes Made of SiC Material for Enhanced Performance

Silicon carbide (SiC) radiation pipes have been making waves in the industry due to their superior performance and versatility. With their ability to withstand high temperatures and harsh environments, these radiation pipes have become a preferred choice for various applications, including nuclear power plants, aerospace, and industrial manufacturing.One of the leading providers of SiC radiation pipes is a company that has carved a niche for itself in the field of advanced materials and engineering solutions. With a strong focus on research and development, the company has been at the forefront of innovation, consistently delivering high-quality products that meet the evolving needs of its customers.The company's SiC radiation pipes are designed to offer maximum thermal conductivity and excellent resistance to corrosion, erosion, and abrasion. This makes them suitable for use in demanding environments where traditional materials may fail to deliver the required performance. Additionally, the company's manufacturing process ensures that the SiC radiation pipes are of the highest quality, guaranteeing long-term reliability and durability.In the field of nuclear power plants, SiC radiation pipes play a crucial role in the safe and efficient operation of reactors. These pipes are used to transfer heat from the reactor core to the coolant, and their ability to withstand high temperatures and intense radiation makes them an ideal choice for this application. The company's SiC radiation pipes have been widely adopted by nuclear power plants around the world, helping to ensure the reliability and safety of these critical facilities.Aerospace is another industry where SiC radiation pipes are finding increasing use. With their lightweight yet strong properties, these pipes are well-suited for use in aircraft engines and propulsion systems. The company's SiC radiation pipes have been utilized in various aerospace applications, where they have demonstrated exceptional performance and contributed to the overall efficiency and reliability of the systems in which they are employed.In industrial manufacturing, SiC radiation pipes play a vital role in processes where high temperatures and harsh conditions are common. Whether in metal processing, chemical production, or heat treatment, these pipes are relied upon to transfer heat while maintaining their structural integrity. The company's SiC radiation pipes have been employed in numerous industrial settings, where they have consistently delivered outstanding performance and proven to be a cost-effective solution for demanding applications.The company's commitment to quality, innovation, and customer satisfaction has helped it become a trusted partner for industries that require advanced materials and engineering solutions. With a dedicated team of experts and state-of-the-art facilities, the company is well-positioned to continue leading the way in the development and production of SiC radiation pipes and other cutting-edge products.As the demand for high-performance materials continues to grow, SiC radiation pipes are expected to play an increasingly important role in various industries. With their unmatched durability, thermal conductivity, and resistance to harsh environments, these pipes offer a reliable solution for critical applications where traditional materials may fall short. And with a company that is dedicated to pushing the boundaries of innovation and excellence, the future looks promising for the continued advancement of SiC radiation pipes and their widespread adoption across diverse industries.

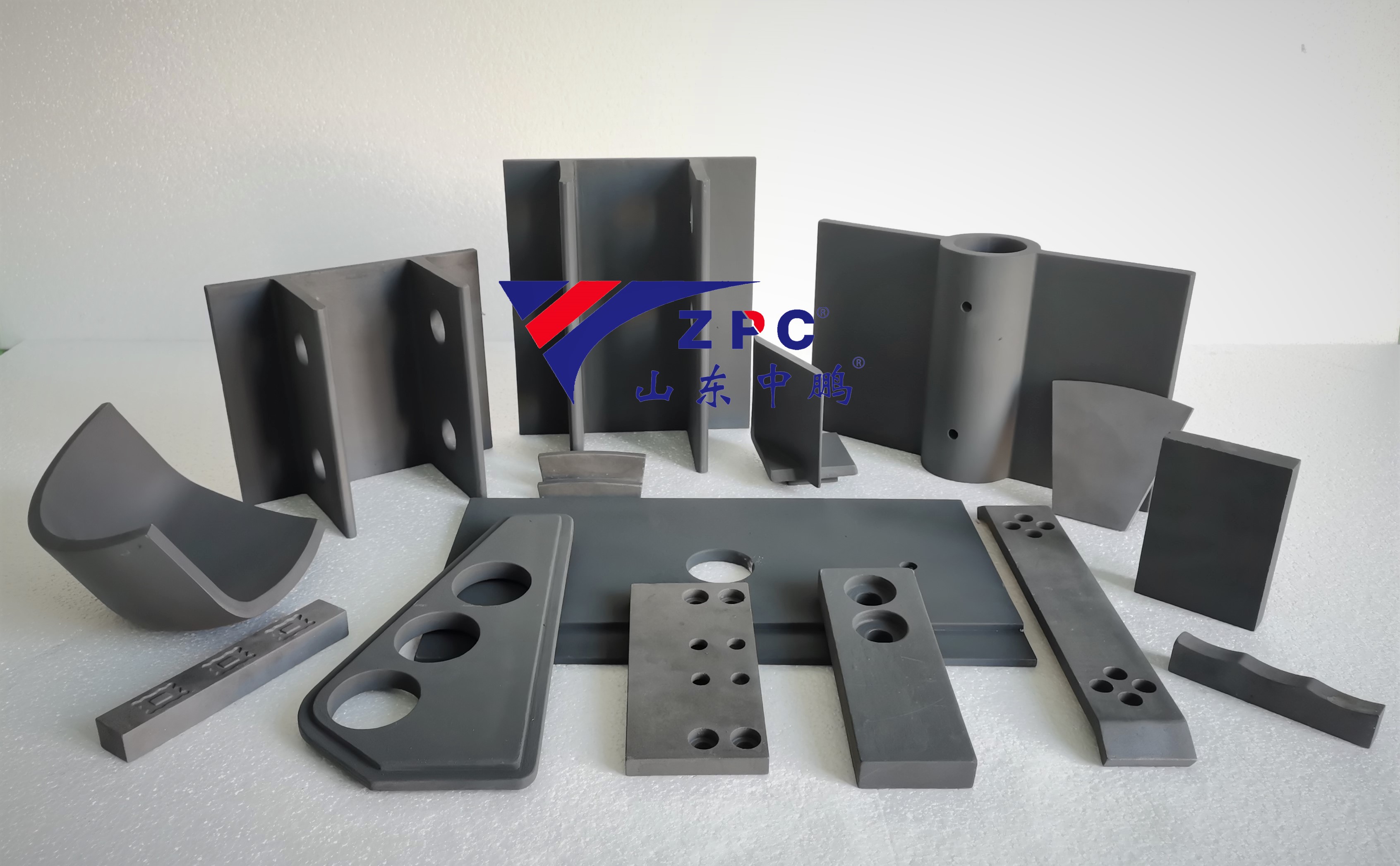

High-quality Silicon Carbide Tiles Manufacturing Facility: Get the Best Products for Your Needs

The Silicon Carbide Tiles Factory is a renowned manufacturing facility located in the heart of the industrial district. The factory boasts state-of-the-art technology and a team of highly skilled engineers, making it one of the leading producers of silicon carbide tiles in the region. With a focus on quality and innovation, the factory has been supplying high-performance silicon carbide tiles to a wide range of industries, including aerospace, defense, energy, and automotive.Established over a decade ago, the factory has continuously invested in research and development to improve its product offerings. The result is a range of silicon carbide tiles that are known for their exceptional strength, durability, and resistance to extreme temperatures and harsh environments. This has made the factory a trusted supplier to some of the most demanding industries in the world.In line with its commitment to innovation, the factory has recently introduced a new line of silicon carbide tiles that are even more advanced and high-performing. These tiles are designed to meet the evolving needs of industries such as aerospace and defense, where superior performance under challenging conditions is essential. By leveraging cutting-edge technology and advanced manufacturing processes, the factory has been able to produce these next-generation silicon carbide tiles without compromising on quality or reliability."We are proud to announce the launch of our latest range of silicon carbide tiles, which represent a significant leap forward in terms of performance and durability," said the factory's spokesperson. "These tiles have undergone rigorous testing and have been proven to outperform existing products in the market. We believe that they will set a new standard for excellence in the industry."The introduction of these advanced silicon carbide tiles has already generated significant interest among current and potential customers. Several major aerospace and defense contractors have expressed keen interest in integrating these tiles into their products and systems, citing the potential for improved performance and reliability. Additionally, the factory has received inquiries from other industries, such as energy and automotive, signaling a growing demand for high-quality silicon carbide tiles across various sectors.To meet this increasing demand, the factory has ramped up its production capacity and streamlined its manufacturing processes. This will ensure that it can fulfill large orders and meet tight deadlines without compromising on quality or consistency. By investing in its production infrastructure, the factory aims to position itself as a reliable and responsive partner to its customers, capable of delivering cutting-edge silicon carbide tiles in a timely manner.The factory's commitment to excellence extends beyond product innovation and manufacturing prowess. It also places a strong emphasis on sustainability and environmental responsibility. Through the implementation of eco-friendly practices and the adoption of energy-efficient technologies, the factory strives to minimize its carbon footprint and contribute to a cleaner, greener future. This commitment to sustainability has earned the factory recognition and accolades from industry peers and regulatory bodies.Looking ahead, the Silicon Carbide Tiles Factory is poised to further strengthen its position as a leader in the silicon carbide tiles industry. By continuing to push the boundaries of innovation, expand its product offerings, and enhance its production capabilities, the factory is well-positioned to meet the evolving needs of its customers and seize new opportunities in the market. With a solid foundation built on technical expertise, reliability, and a customer-centric approach, the factory is set to embark on a new chapter of growth and success.

Promising Silicon Carbide Sleeve Benefits and Applications Revealed in Recent News

Sic Silicon Carbide Sleeve Revolutionizes the Industrial Pump IndustryThe industrial pump industry has always been a crucial part of the global economy, serving various sectors, including oil and gas, wastewater, pulp and paper, and mining. However, with advancements in technology and increased demand for more efficient operations, the industry has continually faced challenges that demand innovative solutions.One of the most significant challenges is dealing with abrasion and corrosion, two issues that reduce equipment longevity, increase operational costs, and compromise overall plant efficiency. Corrosion and abrasion affect pump components such as the casing, impeller, and bearings, which are costly to replace.To address these challenges, Ssic Silicon Carbide Sleeve, a company specializing in pump sleeve technology, has developed a unique solution that's changing the industrial pump industry's landscape. The company's innovative silicon carbide sleeves have proved to be a game-changer, reducing pump downtime, improving efficiency, and reducing operational costs.Ssic Silicon Carbide Sleeve produces high-quality, innovative sleeves from state-of-the-art Silicon Carbide, a material that's both tough and corrosion-resistant. The sleeves' durable design offers exceptional resistance and can withstand harsh conditions for long periods, making them an excellent fit for use in industrial pumps.One advantage of using Ssic Silicon Carbide Sleeves over other materials is their exceptional durability, which reduces downtime and maintenance costs. The sleeves' superior resistance ensures they can withstand high levels of abrasion and corrosion, resulting in a longer lifespan and reduced replacement costs.The company's commitment to quality is evident in its rigorous testing process. Ssic Silicon Carbide Sleeve tests each sleeve's hardness, strength, and thermal conductivity to ensure they meet high-quality standards before release. The sleeves are also certified by international quality management bodies to ensure they're safe and comply with global industry standards.In addition, Ssic Silicon Carbide Sleeve provides education and training opportunities to improve pump operation and maintenance processes. The company has a team of experts with the technical knowledge and experience to work with clients and provide tailored training, consultation, and technical support.Ssic Silicon Carbide Sleeves' versatility has made them a preferred choice for companies in various industries, including oil and gas, mining, and wastewater treatment. The sleeves' robust design allows them to withstand harsh conditions, making them an ideal solution for heavy-duty applications.The Ssic Silicon Carbide Sleeve's impact on the industrial pump industry is not only limited to pump operations but also to environmental conservation. The company's sleeves contribute to environmental conservation by reducing wear and tear on pump components. This, in turn, reduces the amount of waste produced, contributing to a cleaner environment.In conclusion, Ssic Silicon Carbide Sleeve's innovative pump sleeve technology has revolutionized the industrial pump industry by providing a solution to significant challenges such as abrasion and corrosion. The company's Silicon Carbide sleeves offer exceptional resistance, durability, and reliability, making them ideal for use in heavy-duty applications. The sleeves' impact goes beyond pump operations, contributing to environmental conservation and reducing overall operational costs. For any company seeking to increase operational efficiency and reduce maintenance and replacement costs, using Ssic Silicon Carbide Sleeves is a step in the right direction. The company's commitment to quality, innovation, and customer support sets them apart as a leader in the industrial pump industry.

Advanced Radiant Tube Casting for Improved Efficiency and Performance

Dynamic Casting Radiant Tube offers a wide range of high-quality radiant tubes that are essential components in various industrial heating applications. These radiant tubes are meticulously manufactured using a unique dynamic casting process, ensuring superior performance, durability, and efficiency. With a commitment to innovation and excellence, the company has established itself as a trusted leader in the industry, serving a global customer base with their top-of-the-line products.The dynamic casting process used by the company to produce radiant tubes sets them apart from the competition. This advanced technique involves the use of centrifugal force to create a seamless, dense, and finely grained structure within the radiant tubes. As a result, the tubes exhibit exceptional resistance to thermal shock, corrosion, and mechanical stress, making them ideal for the most demanding applications in industries such as steel, aluminum, automotive, and aerospace.In addition to their superior quality, Dynamic Casting Radiant Tube also offers a diverse range of radiant tube designs to meet the specific needs of their customers. Whether it's a single-ended radiant tube, U-shaped radiant tube, W-shaped radiant tube, or any custom configuration, the company has the expertise and capability to deliver tailored solutions that optimize the heating processes in various industrial facilities.Moreover, the company takes pride in its team of highly skilled engineers, metallurgists, and technicians who are dedicated to ensuring the quality and performance of every radiant tube that leaves their facility. Through continuous research and development, they continuously improve their products and processes to stay at the forefront of technological advancements and industry standards.With a strong focus on customer satisfaction, Dynamic Casting Radiant Tube strives to provide unparalleled support and service to their clients. From product selection and customization to installation and maintenance, the company works closely with customers to ensure that their radiant tubes deliver maximum value and performance throughout their service life.Furthermore, the company's commitment to environmental sustainability is evident in its manufacturing processes. By adhering to strict environmental regulations and implementing eco-friendly practices, Dynamic Casting Radiant Tube minimizes its carbon footprint and contributes to a cleaner and greener future for the industry.As a global supplier, Dynamic Casting Radiant Tube has built a solid reputation for delivering top-notch products and services to customers worldwide. Their seamless distribution network and reliable logistics partners ensure that radiant tubes reach clients on time, regardless of their location.In conclusion, Dynamic Casting Radiant Tube is a leading provider of high-performance radiant tubes that cater to a wide spectrum of industrial heating applications. With their cutting-edge dynamic casting technology, diverse product offerings, commitment to quality, and customer-centric approach, the company continues to set the benchmark for excellence in the industry. Moving forward, Dynamic Casting Radiant Tube remains dedicated to innovation, sustainability, and exceeding customer expectations, solidifying its position as a preferred partner for industrial heating solutions.

Ultimate Guide to Flame Tests for Building Materials: A Comprehensive Analysis

Building Materials Flame Test: Ensuring Safety and QualityIn the pursuit of safe and durable construction, the importance of building materials cannot be overstated. Whether it be for residential homes, commercial buildings, or infrastructure projects, the quality and safety of the materials used can directly impact the lifespan and integrity of a structure. To address these concerns, a renowned building material company has introduced an innovative flame test to ensure the highest levels of safety and quality in their products.The flame test, developed by the company's expert team of engineers and scientists, serves as a critical step in the quality control process. By subjecting their products to rigorous testing procedures, they aim to identify potential weaknesses and vulnerabilities in the materials that could lead to fire hazards. This meticulous approach not only demonstrates their commitment to ensuring customer safety but also enhances their reputation as a leading provider of reliable and trustworthy building materials.The flame test procedure involves exposing various samples of the company's building materials to controlled flames of varying intensities. The materials are carefully observed and analyzed to determine their reaction to heat, flame, and combustion. This comprehensive evaluation allows the company to evaluate their products' resistance to fire and identify any areas of improvement necessary to meet or exceed industry standards.The test covers a wide range of building materials offered by the company, including insulation materials, structural components, and finishing products. By subjecting each material to such tests, they are able to provide customers with detailed information about the fire-resistant properties of these materials. This transparency allows builders, architects, and homeowners to make informed decisions regarding the materials they choose for their projects, ensuring the safety and longevity of the structures they construct.The flame test results are documented and compiled into an extensive database, which is made available to customers along with detailed technical specifications. These documents enable customers to assess the fire-safe characteristics of each product and make educated choices tailored to their specific needs. Moreover, the company remains committed to regularly updating this database to include new materials as they are developed, thus staying at the forefront of fire safety technology in the construction industry.Beyond the immediate benefits of ensuring safety and quality, the flame test has wider implications for the construction industry as a whole. By promoting the use of fire-resistant materials, the company not only contributes to creating safer environments but also assists in the prevention and mitigation of fire-related accidents. With building fires being a significant global concern, embracing fire-safe materials becomes crucial in reducing the loss of life and property in such incidents. The introduction of the flame test by this pioneering company highlights their dedication to making a positive impact in the realm of construction safety.This commitment extends to the research and development efforts of the company. They continuously strive to innovate and improve their products, using the findings from the flame tests as a foundation for their advancements. This dedication to pushing the boundaries of fire safety technology has earned them recognition and accolades within the industry, solidifying their position as a leader in the field.In conclusion, the introduction of the flame test by this renowned building material company signifies their unwavering commitment to safety, quality, and innovation. By subjecting their products to rigorous testing procedures, they ensure the highest standards of fire resistance, providing customers with peace of mind when using their materials. Furthermore, their efforts contribute to the larger goal of preventing fire-related accidents and safeguarding lives and property. As the construction industry continues to prioritize safety, the flame test serves as a testament to this company's dedication to driving positive change in the field of building materials.

Efficient FGD Slurry Spray Piping Solution for Coal-Fired Power Plants

FGD Slurry Spray Piping: The Key to Effective Flue Gas DesulfurizationThe environmental impact of coal-fired power plants has been a topic of concern for many years. In particular, the need to reduce emissions of sulfur oxides (SOx) has led to the widespread adoption of flue gas desulfurization (FGD) systems. These systems remove sulfur dioxide (SO2) from the flue gas before it is released into the atmosphere, thereby reducing the emissions of this harmful gas.FGD systems typically involve the use of chemical scrubbers, which react with the SO2 in the flue gas to form a slurry. This slurry is then sprayed onto a surface, where the moisture evaporates, leaving behind a residue of solid particles. The residue is then removed and disposed of, usually in a landfill.The spray piping used in FGD systems is critical to their performance. The piping must be able to withstand the corrosive nature of the slurry, which contains a variety of chemicals. In addition, the piping must be able to deliver the slurry with sufficient force to ensure effective scrubbing of the flue gas.RPS Composites, Inc. has developed a range of FGD slurry spray piping solutions that meet these requirements. Their AA Series of piping is made from fiber-reinforced plastic (FRP), which provides excellent corrosion resistance and durability. The piping is also lightweight, easy to install, and requires minimal maintenance.One of the keys to the effectiveness of FGD systems is the angle at which the slurry is sprayed onto the scrubbing surface. RPS Composites offers a range of 90° FGD spray nozzles that ensure optimal coverage and scrubbing efficiency. These nozzles are designed to deliver the slurry with a consistent flow and pressure, ensuring that all areas of the scrubbing surface receive adequate coverage.In addition to the AA Series of spray piping and 90° FGD spray nozzles, RPS Composites also offers a range of other FGD system components, including pumps, valves, and ductwork. Their expertise in the design and manufacture of these components has made them a leading supplier to the power generation industry.In conclusion, FGD systems are an essential component of efforts to reduce the environmental impact of coal-fired power plants. Effective FGD slurry spray piping is critical to the performance of these systems, and RPS Composites offers a range of solutions that meet the requirements of this challenging application. With their AA Series of spray piping and 90° FGD spray nozzles, power plant operators can be confident of achieving optimal scrubbing efficiency and compliance with environmental regulations.

Flame Arrestor Market to Witness Growth with Key Players in 2022

HHO Flame Arrestor: Ensuring Safety and EfficiencyIn various industries, the use of HHO gas has become increasingly popular due to its numerous benefits. HHO gas, also known as oxyhydrogen gas, is created through the process of electrolysis and is used as a supplement to traditional fuels to improve combustion efficiency and reduce emissions. However, like any other gas or flammable substances, HHO gas poses a potential risk of fire or explosion during storage, transportation, and use. Therefore, it is essential to have proper safety measures in place, and one of the most important devices in this regard is the HHO flame arrestor.What is an HHO Flame Arrestor?An HHO flame arrestor is a safety device that prevents flames from propagating through pipelines or vessels that contain flammable gases or liquids. In other words, it acts as a mechanical barrier or obstacle that inhibits the movement of flames while allowing the flow of gases or liquids. Flame arrestors work based on the principle of heat loss. When a flame ignites the flammable mixture in the pipeline, it generates heat that gets dissipated as it passes through flame arrestors' metal plates or mesh screens. The temperature drop prevents the flame from reaching the other side of the arrestor, thus protecting equipment, personnel, and the environment from damage or harm.Applications of HHO Flame ArrestorsHHO flame arrestors are essential devices across various industries that deal with flammable gases or liquids. These include:1. Oil and Gas Industry: HHO gas is widely used in the oil and gas industry, especially in drilling operations, production, and transportation. Flame arrestors are used in pipelines, storage tanks, and other equipment to prevent explosions and fires.2. Chemical Industry: The chemical industry uses a wide range of flammable liquids and gases. Flame arrestors are used extensively in reactors, distillation columns, and other processing equipment.3. Marine Industry: Flame arrestors play a critical role in the marine industry, where flammable gases are generated during cargo loading and unloading, ship-to-ship transfers, and engine operations.4. Automotive Industry: HHO generators are increasingly finding use in the automotive industry to improve fuel efficiency and reduce emissions. Flame arrestors are installed in the HHO pipelines to prevent accidents.Leading Manufacturers of HHO Flame ArrestorsThe HHO flame arrestor market is highly competitive, with several companies offering a wide range of products. Here are some of the leading manufacturers of HHO flame arrestors:1. Ermacora: Ermacora is an Italian company that specializes in the production of flame arrestors and other safety devices for industrial applications. Their products are known for their durability, reliability, and high-performance.2. Emerson Electric Co.: Emerson Electric Co. is a global leader in providing innovative solutions for industrial automation, process control, and safety. Their flame arrestors are designed to meet the stringent safety requirements of various industries.3. Braunschweiger Flammenfilter: Braunschweiger Flammenfilter GmbH is a German company that manufactures high-quality flame arrestors and other safety products. They have decades of experience in the field and have an extensive portfolio of products.4. L&J Technologies: Based in Minnesota, USA, L&J Technologies is a leading provider of safety systems, including flame arrestors. Their products are designed to address the specific requirements of different industries and ensure safety and efficiency.ConclusionThe use of HHO gas has several advantages, but it also poses a potential risk of fire and explosion. HHO flame arrestors play a critical role in preventing such accidents and ensuring safety and efficiency. Therefore, it is essential to choose the right manufacturer and device that meets your needs and complies with the relevant safety standards. With the increasing demand for environment-friendly fuels and technologies, HHO flame arrestors are becoming an integral part of various industries worldwide.