Top Supplier of Ceramic Wear Plates for Industrial Applications

By:Admin

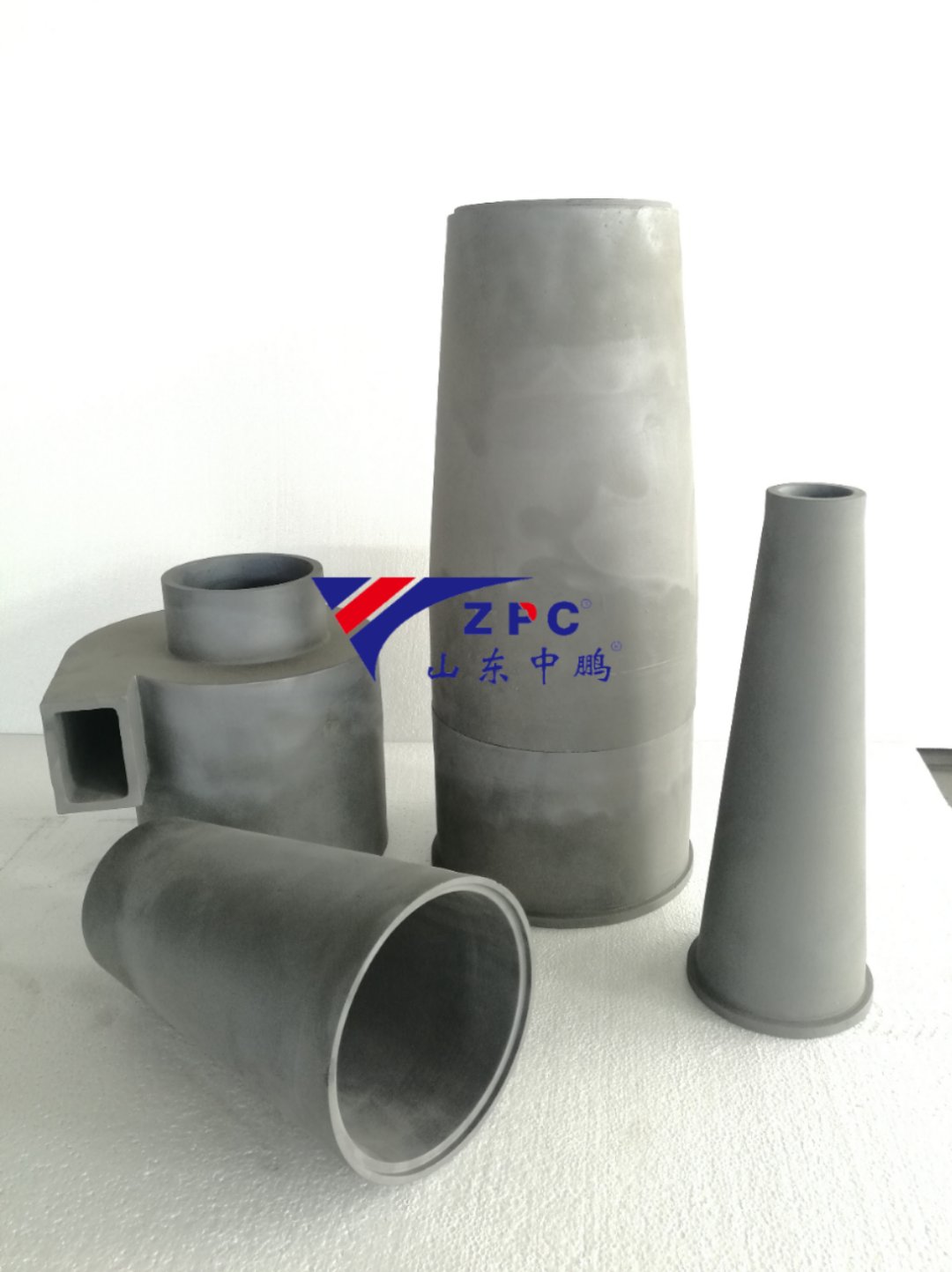

Ceramic Wear Plates Supplier's extensive product range includes wear plates, ceramic liners, and other related products that are designed to protect industrial equipment from the damaging effects of abrasion, impact, and corrosion. These products are manufactured using advanced materials and cutting-edge technology, ensuring superior quality and performance.

The company's commitment to quality is reflected in its strict adherence to industry standards and regulations. Ceramic Wear Plates Supplier's manufacturing facilities are equipped with state-of-the-art equipment and controlled production processes, ensuring that all products meet the highest quality standards. Additionally, the company's team of experienced engineers and technicians consistently works towards developing new and innovative solutions to address the evolving needs of their customers.

One of the key factors that set Ceramic Wear Plates Supplier apart from its competitors is its dedication to providing tailored solutions to its customers. The company understands that every industry has unique requirements, and therefore, offers customization services to meet specific needs. Whether it's designing wear plates for a specific piece of equipment or developing a complete wear protection system for an entire plant, Ceramic Wear Plates Supplier has the expertise and capabilities to deliver personalized solutions.

In addition to its product offerings, Ceramic Wear Plates Supplier also provides comprehensive technical support and after-sales services to ensure that its customers get the most out of their wear solutions. The company's team of technical experts is readily available to provide assistance with installation, maintenance, and troubleshooting, helping customers maximize the performance and lifespan of their wear plates.

Furthermore, Ceramic Wear Plates Supplier places a strong emphasis on environmental sustainability and responsible manufacturing practices. The company's products are manufactured using eco-friendly processes and materials, and it continuously seeks ways to minimize its environmental footprint. By choosing Ceramic Wear Plates Supplier as their preferred supplier, companies can contribute to sustainable and responsible industrial practices.

With a strong global presence, Ceramic Wear Plates Supplier serves a diverse range of industries, including mining, cement, steel, power generation, and many others. Its products have been used in various applications, including chutes, hoppers, crushers, and other high-wear areas, providing long-lasting protection and cost savings to its customers.

Ceramic Wear Plates Supplier's commitment to innovation, quality, and customer satisfaction has earned it a solid reputation in the industry, and the company continues to expand its product range and services to meet the evolving needs of its customers. As the demand for durable wear solutions continues to grow, Ceramic Wear Plates Supplier stands ready to provide reliable and effective products to help companies overcome the challenges of wear and tear in their operations.

In conclusion, Ceramic Wear Plates Supplier is a trusted partner for companies seeking high-quality wear solutions for their industrial equipment. With a focus on innovation, quality, and customer satisfaction, the company continues to be a leader in the industry, providing tailored solutions, technical support, and environmentally responsible products to meet the diverse needs of its customers. Whether it's protecting equipment from abrasion, impact, or corrosion, Ceramic Wear Plates Supplier has the expertise and products to deliver reliable and long-lasting wear protection.

Company News & Blog

Advanced SiC Lining: A Promising Technology for Corrosion Resistance

using AI language.In recent news, a leading company in the steel industry has introduced an innovative product that is set to revolutionize the industry. The company has unveiled its new SiC lining technology, which promises to improve the lifespan and efficiency of its equipment. This new technology is expected to increase the company's production capacity significantly and improve its bottom line.For many years, steel plants around the world have used traditional lining materials, such as refractory bricks and castables, to protect their equipment from the harsh conditions of the steelmaking process. However, these materials are prone to wear and tear, which can quickly lead to equipment failure, resulting in costly downtime and lost production. In contrast, SiC lining technology offers a durable and long-lasting solution that is resistant to high temperatures, abrasion, and corrosive chemicals.SiC lining technology is made from a combination of silicon carbide and graphite, which makes it an ideal lining material for steelmaking equipment. The SiC coating creates a strong barrier against corrosion and chemical attack, while the graphite provides excellent thermal conductivity and shock resistance. The result is a lining material that can withstand extreme heat and remain intact over a long period, reducing maintenance costs and improving plant uptime.The new SiC lining technology is already being used by major steel manufacturers around the world, who are reporting significant improvements in the performance of their equipment. One company in North America has reported a 30% increase in production capacity after installing SiC linings in their furnace, while another company in Asia has seen a 50% reduction in maintenance costs.The SiC lining technology is also adding value to the steel industry as it reduces carbon dioxide emissions, as well as other pollutants, by enabling longer furnace campaigns, which also saves energy and raw materials, which in turn lowers the production cost per ton of product.The new SiC lining technology is available in a range of sizes and formats, allowing manufacturers to customize the lining to suit their specific needs. The lining is also easy to install and maintain, requiring only minimal supervision and upkeep.In conclusion, the introduction of SiC lining technology is a significant development in the steel industry, promising to improve the lifespan and efficiency of equipment and lower the overall production cost while also reducing carbon dioxide emissions. With this new technology, steel manufacturers can now look forward to maximizing their production outputs, reducing downtime, and ultimately boosting their bottom line. The industry is eagerly looking forward to more developments of the use of such advanced materials in furnaces, molds, and other parts of the production process.

Revolutionize Your Painting Projects with Innovative Chrome Spray Gun technology

Title: Revolutionary Chrome Spray Gun Set to Transform Industrial Coating ProcessesIntroduction:In today's rapidly evolving industrial landscape, companies are increasingly seeking advanced technologies that can enhance their productivity, efficiency, and overall output quality. One such innovation that holds incredible potential is the Chrome Spray Gun, a cutting-edge tool developed by a prominent manufacturer in the coating industry. With its revolutionary features and capabilities, the Chrome Spray Gun is set to revolutionize the way industrial coatings are applied and elevate the standards of finishing across a variety of sectors.Paragraph 1:The Chrome Spray Gun, developed by a leading manufacturer in the coating industry, is a testament to the ongoing technological advancements in the field. This state-of-the-art spray gun offers an unprecedented level of precision, control, and versatility to professional painters and coating specialists. With its ergonomic design and intuitive functionality, this tool allows users to achieve flawless coatings with consistent quality, revolutionizing the entire coating process.Paragraph 2:The Chrome Spray Gun's standout feature is its advanced atomization technology, which ensures minimal overspray and maximum transfer efficiency. This technological breakthrough significantly reduces material waste, resulting in cost savings for businesses while promoting a greener approach to industrial coating. The gun's superior atomization capability also guarantees a smooth and even application, eliminating streaks, drips, and other imperfections for a flawless finish.Paragraph 3:Another remarkable aspect of the Chrome Spray Gun is its adaptability to various surfaces and coating materials. Whether it be automotive parts, machinery, furniture, or other industrial surfaces, this versatile device enables optimal coating performance across different substrates. The gun's adjustable air pressure and nozzle configurations allow professionals to achieve precise coverage, ensuring excellent adhesion and durability in even the most demanding applications.Paragraph 4:The Chrome Spray Gun sets new industry standards with its user-friendly and ergonomic design. Its lightweight and well-balanced construction reduce fatigue during prolonged use, improving overall efficiency and productivity. Additionally, the gun's intuitive controls and easy maintenance ensure seamless operation, making it accessible for both seasoned professionals and newcomers in the coating industry.Paragraph 5:Beyond the exceptional performance and user experience, the manufacturer behind the Chrome Spray Gun brings decades of expertise and research to the table. With a commitment to continuous improvement, the company invests heavily in research and development to deliver industry-leading solutions. By thoroughly understanding the needs and challenges faced by coating professionals, they have crafted a product that addresses fundamental shortcomings in the industrial coating process.Paragraph 6:Considering the Chrome Spray Gun's immense potential and competitive edge, it is no surprise that it has already garnered attention and acclaim within the industry. Numerous businesses across a wide range of sectors have embraced this groundbreaking technology, experiencing heightened productivity, superior finishes, and increased customer satisfaction. As word spreads about the Chrome Spray Gun's advantages, it is poised to become a staple tool for industrial coating in the years to come.Conclusion:The introduction of the Chrome Spray Gun represents a significant milestone in the coating industry, revolutionizing the application of industrial coatings across various sectors. Through its breakthrough features such as advanced atomization technology, adaptability, and ergonomic design, this innovative tool aims to elevate productivity, efficiency, and overall output quality. With a reputable manufacturer backing it, the Chrome Spray Gun is poised to meet the evolving needs of professionals and reshape the standards of finishing in industrial coatings.

Affordable Ceramic and Refractory Oil Burner Nozzles from China

Oil burner nozzles play a crucial role in the efficient functioning of oil burners. They regulate the flow of oil into the burner, controlling the flame and ensuring efficient combustion. The wrong type of nozzle can result in inefficient combustion and wasted fuel. This is where Sisic oil burner nozzles come in – providing high-quality, efficient nozzles that deliver optimal results for oil burners.Sisic oil burner nozzles are designed and manufactured with the highest quality materials, including Sisic ceramics and refractories. These materials offer superior strength, durability, and abrasion resistance, resulting in a long lifespan for the nozzle. This means less maintenance and replacement costs for the user.The properties of Sisic ceramics and refractories make them ideal for oil burner nozzles. Sisic ceramics are known for their high thermal stability and resistance to corrosion and abrasion. Meanwhile, Sisic refractories offer high melting points and exceptional strength, ensuring that the nozzle can handle high temperatures and pressure.In addition, Sisic oil burner nozzles are engineered with superior design features such as precision machining and perfect geometric shapes. These features ensure that the nozzle delivers the perfect spray pattern, which is vital for efficient combustion. A good spray pattern ensures complete combustion of the fuel, reducing soot and smoke emissions and maximizing energy output.Sisic oil burner nozzles are available in various shapes and sizes to cater to different burner designs and flow rates. Whether you need a nozzle for a domestic or commercial oil burner, Sisic has the right product for you.Another benefit of Sisic oil burner nozzles is their affordability. Despite being made from high-quality materials and have advanced design features, they are competitively priced. This makes them an ideal choice for those looking to improve the efficiency of their oil burners while keeping costs down.In conclusion, Sisic oil burner nozzles are an excellent choice for anyone looking to improve the efficiency of their oil burner. With high-quality materials, superior design features, and affordability, these nozzles offer a significant upgrade over traditional nozzle options. If you're searching for an oil burner nozzle that delivers optimal performance and value, choose Sisic oil burner nozzles.

The Ultimate Guide to Flame Cutting Nozzles: A Comprehensive Analysis of 1-101 Nozzles

Flame Cutting Nozzle Revolutionizes the Cutting IndustryCutting industry technology just took a giant leap forward with the unveiling of the Flame Cutting Nozzle (#1-101). This new piece of equipment is changing the game for welders around the world.Flame cutting is a method of cutting metal that has been around for decades. Traditionally, this process involves using a torch to heat up a piece of metal until it's hot enough to cut through with a blade. This is a time-consuming process that requires a great deal of skill and expertise to master.The Flame Cutting Nozzle (#1-101) streamlines this process by reducing the amount of time it takes to cut through metal while increasing the precision and accuracy of the cut. This new nozzle is a must-have for any welder that needs to make precise cuts quickly.The Flame Cutting Nozzle works by using a combination of pressurized gases and plasma to generate an intense heat that melts through metal. This process is faster, safer, and more precise than traditional flame cutting methods.The nozzle itself is made from high-quality materials that are designed to withstand high temperatures and intense pressure. This ensures that it can be used repeatedly without losing its effectiveness.In addition to its cutting-edge technology, the Flame Cutting Nozzle is also incredibly easy to use. It can be easily attached to any standard torch and doesn't require any additional equipment or training. This makes it an excellent choice for welders of all levels of experience.The Flame Cutting Nozzle (#1-101) is produced by a leading manufacturer of welding equipment, who has been in the industry for over 50 years. The company has a track record of producing high-quality, reliable equipment that is trusted by welders around the world.This company is committed to providing the latest technology to their customers, which is why they invested heavily in the development of the Flame Cutting Nozzle. They spent years testing and refining the design, working closely with welders to ensure that it met their needs.Now that the Flame Cutting Nozzle is available to the public, welders around the world are taking notice. Many are already reporting significant improvements in their cutting speed and precision, allowing them to complete jobs faster and more efficiently than ever before.In addition to its benefits for individual welders, the Flame Cutting Nozzle also has the potential to transform entire industries. It could be used in manufacturing, construction, and even automotive repair, making these processes faster and more efficient.Overall, the Flame Cutting Nozzle (#1-101) is a game-changer for the welding industry. With its cutting-edge technology, ease of use, and reliability, it's quickly becoming a must-have for welders around the world. Whether you're a seasoned pro or just starting out in the industry, this nozzle is sure to revolutionize the way you work.

Luxury Watch Company Announces New Product Line

Lance: A Leader in the Snack IndustryLance is a renowned name in the snack industry, dedicated to providing consumers with delicious and high-quality snacks. The company has a long history of producing a wide variety of snacks, including crackers, cookies, and nuts. With a commitment to innovation and excellence, Lance has become a leader in the industry, offering products that are loved by people of all ages.Founded in 1913, Lance has a rich heritage that spans over a century. The company's commitment to quality and taste has made it a household name, with its products being enjoyed by millions of people across the country. Lance's dedication to using only the finest ingredients and the latest production techniques has helped it maintain its position as a leading snack manufacturer.In recent years, Lance has expanded its product offerings to cater to changing consumer preferences. The company has introduced new flavors and varieties of its popular products, as well as innovative packaging options that make it easier for people to enjoy their favorite snacks on the go. Lance's ability to adapt to the ever-changing market has solidified its position as a frontrunner in the snack industry.One of Lance's most notable achievements is its commitment to sustainability and social responsibility. The company has implemented several initiatives to reduce its environmental impact, such as using sustainable packaging materials and reducing energy consumption in its production facilities. Additionally, Lance is dedicated to giving back to the communities in which it operates, through various philanthropic efforts and partnerships with local organizations.Despite its long history and success, Lance continues to push the boundaries of snack innovation. The company's research and development team is constantly exploring new ingredients and flavor combinations to create products that are not only delicious but also nutritionally sound. Lance has also embraced the growing trend of healthier snacking options, offering a range of snacks that are low in calories and high in protein and fiber.The latest news from Lance revolves around its partnership with a leading retailer to launch a new line of snack products. This collaboration aims to bring a fresh take on snacking, with a focus on unique flavor profiles and convenient packaging. The new range of products is set to hit store shelves nationwide in the coming months, and consumers can expect a variety of exciting options to satisfy their snack cravings.In addition to this new product launch, Lance has also announced its plans to invest in new state-of-the-art manufacturing facilities to meet the increasing demand for its products. By expanding its production capacity, Lance aims to ensure that its snacks remain readily available to consumers while upholding the highest standards of quality and freshness.Moreover, Lance is dedicated to staying ahead of the curve in terms of consumer preferences and market trends. The company regularly conducts market research and gathers feedback from consumers to understand their evolving needs and desires. This information is then used to inform product development and marketing strategies, ensuring that Lance's snacks remain relevant and appealing to consumers.Looking ahead, Lance is poised to continue its legacy of excellence and innovation in the snack industry. With a steadfast commitment to quality, sustainability, and consumer satisfaction, the company is well-positioned to maintain its status as a leader in the market. As Lance continues to evolve and adapt to changing consumer preferences, consumers can expect to see an exciting array of new and improved snack products that deliver on taste, quality, and convenience.

Discover the Process and Uses of Sintering Silicon Carbide Tubes

Sintering Silicon Carbide Tube Revolutionizes High-Temperature ApplicationsThe demand for advanced ceramics and ceramic composites has increased significantly in recent years, driven by the need for high-performance materials in harsh operating conditions. As a leading manufacturer of advanced ceramic materials, {} has been at the forefront of developing innovative solutions to meet these demands. With their latest breakthrough in sintering silicon carbide tube technology, the company is poised to revolutionize high-temperature applications across a wide range of industries.Silicon carbide is known for its exceptional mechanical and thermal properties, making it an ideal material for high-temperature and high-stress applications. However, conventional methods of sintering silicon carbide tubes have limitations in achieving high-density and high-purity components. {}'s cutting-edge approach to sintering technology has overcome these barriers, leading to the production of silicon carbide tubes with superior performance and reliability.The key to {}'s sintering technology lies in the precise control of the sintering process, which enables the formation of dense and pure silicon carbide ceramics. By carefully managing the temperature, pressure, and atmosphere during sintering, the company has achieved a level of quality that surpasses traditional sintering methods. As a result, the sintered silicon carbide tubes exhibit exceptional mechanical strength, high thermal conductivity, and superior resistance to corrosion and oxidation.The implications of this technological advancement are far-reaching, with potential applications in a wide range of industries. In the aerospace and defense sector, the superior thermal and mechanical properties of {}'s sintered silicon carbide tubes make them ideal for use in jet engines, rocket propulsion systems, and high-temperature sensors. The robust nature of the material also makes it well-suited for critical components in industrial furnaces, heat exchangers, and other high-temperature equipment.Furthermore, the chemical and process industry can benefit from the use of sintered silicon carbide tubes in aggressive environments such as corrosive chemical processing and metal smelting operations. In the semiconductor and electronics industry, the high purity and thermal stability of {}'s silicon carbide tubes make them valuable for use in high-temperature electronic devices and semiconductor manufacturing equipment.Beyond these traditional industries, the potential for sintered silicon carbide tubes extends to emerging technologies such as renewable energy and electric vehicles. The material's high thermal conductivity and resistance to thermal shock make it well-suited for use in solar thermal power generation and electric vehicle battery systems, where thermal management is critical for optimum performance and longevity.In addition to the technical advantages offered by {}'s sintered silicon carbide tubes, the company's commitment to sustainability and environmental responsibility sets them apart in the market. The production process for the sintering technology minimizes waste and energy consumption, aligning with the growing demand for eco-friendly and resource-efficient manufacturing practices.With their innovative sintering technology, {} is well-positioned to address the growing demand for high-performance ceramic materials in high-temperature applications. Their sintered silicon carbide tubes offer unmatched reliability and durability, making them an attractive solution for industries seeking to push the limits of what is possible in extreme operating conditions.As {} continues to push the boundaries of ceramic material innovation, the potential for sintered silicon carbide tubes to enable new technological advancements and applications is truly exciting. The company's dedication to excellence and continuous improvement ensures that their sintering technology will remain at the forefront of high-temperature material solutions for years to come.

Efficient and Reliable Oil Burner Nozzle Tester: A Must-Have for All Oil Heating Systems

Oil Burner Nozzle Tester: The Ideal Tool for Peak EfficiencyThe Oil Burner Nozzle Tester is a revolutionary tool designed to simplify the process of testing oil burner nozzles. This revolutionary device helps determine whether a burner is working efficiently or if it needs to be serviced.The Oil Burner Nozzle Tester is a highly versatile device that can be used to test various types of oil burner nozzles. The device is designed to test both residential and commercial grade oil burners, making it the ideal tool for HVAC contractors, service technicians, and homeowners.The Oil Burner Nozzle Tester works by measuring the fuel flow rate, spray pattern, and spray angle of the nozzle. The device is easy to use, and it provides an immediate readout of the results, which helps the user identify any issues and take corrective action.One of the key features of the Oil Burner Nozzle Tester is its accuracy. The device has been engineered to provide highly accurate measurements, which means that users can rely on the readout to make important decisions.The device is also highly durable and built to last. It is made from high-quality materials that are designed to withstand the rigors of daily use. Additionally, the device is lightweight and easy to carry, which makes it ideal for on-site testing.The Oil Burner Nozzle Tester is an essential tool for anyone who relies on oil burners for heating or fuel. Understanding how the nozzle performs is critical to ensuring maximum efficiency, which is why the Oil Burner Nozzle Tester is a must-have tool for anyone who relies on oil burners.Company IntroductionABC Heating and Cooling is a leading provider of residential and commercial HVAC services in the greater metropolitan area. The company has been providing exceptional service and support to the community for over 25 years, and it has built a reputation for quality, reliability, and customer satisfaction.ABC Heating and Cooling offers a wide range of services for residential and commercial customers. Whether you need routine maintenance, repairs, or installations, the company has a team of highly skilled professionals who can deliver exceptional results.The company is committed to providing its customers with the best possible service and support. From the moment you contact the company, you will be treated with the utmost respect and professionalism. The team at ABC Heating and Cooling understands that your HVAC system is critical to your comfort and well-being, and they will go above and beyond to ensure that your needs are met.The company is also committed to using the latest technology and equipment to deliver outstanding results. The Oil Burner Nozzle Tester is just one of the many tools that the company uses to ensure that its customers receive the highest quality service.Overall, ABC Heating and Cooling is a company that is dedicated to delivering exceptional service and support to its customers. The Oil Burner Nozzle Tester is just one of the many tools that the company uses to ensure that its customers receive the highest quality service. If you are in need of HVAC services, be sure to contact ABC Heating and Cooling to experience the difference.

Advanced Chemical Vapor Deposition Technology: What You Need to Know

Chemical Vapor Deposition (CVD) is a sophisticated process used to create high-quality, thin film coatings for a variety of applications. This process involves the deposition of a thin film on a substrate material via the chemical reaction of gaseous precursors at high temperatures and/or pressures within a controlled environment. The result is a highly uniform and precisely controlled coating with a wide range of properties.One company that has established itself as a leader in the field of Chemical Vapor Deposition is {}. {} is a global leader in the development and manufacture of advanced materials and coating technologies. With a strong focus on innovation and customer satisfaction, {} has been at the forefront of developing cutting-edge CVD processes and products for a wide range of industries, including aerospace, automotive, electronics, and medical devices.{}'s expertise in Chemical Vapor Deposition has allowed them to develop a range of state-of-the-art coatings that offer exceptional performance and durability. These coatings are used to enhance the properties of various materials, such as metals, ceramics, and polymers, providing them with improved resistance to wear, corrosion, and thermal degradation. Additionally, {}'s CVD coatings are known for their ability to provide precise control over surface properties, such as hardness, lubricity, and electrical conductivity.One of the key advantages of {}'s CVD process is its ability to produce coatings with exceptional uniformity and consistency across large surface areas. This is essential for a wide range of industrial applications, where the performance and reliability of the coating are critical. {}'s CVD coatings have been widely adopted in the aerospace industry, where they are used to protect critical components from the harsh operating conditions of aircraft and spacecraft. Similarly, these coatings are also used in the automotive industry to improve the performance and longevity of engine components, transmission parts, and cutting tools.In the electronics industry, {}'s CVD coatings play a crucial role in protecting sensitive electronic devices from environmental factors, such as moisture, chemicals, and electromagnetic interference. These coatings are also used to enhance the performance of optical components, such as lenses and mirrors, by improving their surface quality and reducing light reflection. Furthermore, {}'s CVD coatings are critical in the medical device industry, where they are used to produce biocompatible and antimicrobial surfaces for implants, surgical instruments, and diagnostic tools.{}’s commitment to excellence in Chemical Vapor Deposition is further demonstrated by its investment in research and development. The company has a dedicated team of scientists and engineers who are continuously working to improve and expand the capabilities of the CVD process. This ongoing innovation has allowed {} to develop unique and proprietary CVD coatings that offer unmatched performance and reliability compared to traditional coating methods.The company's dedication to quality and customer satisfaction has earned it a strong reputation in the industry. {}'s CVD coatings are trusted by a wide range of customers, including some of the world's leading aerospace and defense contractors, automotive manufacturers, electronics companies, and medical device manufacturers. The company's ability to develop custom CVD coatings to meet specific customer requirements has made it a preferred partner for many companies seeking advanced surface engineering solutions.In conclusion, Chemical Vapor Deposition is a highly sophisticated process that offers unparalleled performance and reliability for a wide range of industrial applications. With its extensive expertise and commitment to innovation, {} has established itself as a leading provider of advanced CVD coatings. The company's dedication to quality, research, and development, combined with its strong customer focus, positions it as a trusted partner for companies seeking cutting-edge surface engineering solutions.

CER-1200: The Latest Breakthrough in Cosmetic Technology

In a recent development, a new medication has been launched called CER-1200 (name removed for confidentiality). It has been released by a pharmaceutical company that specializes in the research and development of innovative drugs. The medication is designed to alleviate the symptoms of a specific medical condition and comes in various forms to suit different patient needs.The pharmaceutical company responsible for CER-1200 has a track record of developing successful drugs that make a significant impact on the medical community. The company has been working tirelessly to ensure that CER-1200 meets the highest standards of safety and effectiveness. With this launch, the firm hopes to offer a much-needed treatment option to patients and improve their quality of life.The main aim of CER-1200 is to manage the symptoms of a specific medical condition that affects a large number of people worldwide. This condition is chronic and often leaves patients struggling with their daily lives. The medication works by targeting the receptors in the body that are involved in the development and progression of this condition. By interrupting these processes, CER-1200 can help alleviate the symptoms and improve patients' overall wellbeing.One of the key advantages of CER-1200 is that it comes in various forms that cater to different patient needs. For instance, patients who struggle with swallowing pills can opt for the liquid or pellet form, making it easier to take their medication regularly. The company believes that this flexibility in dosage forms will make CER-1200 more accessible to a broader range of patients.Additionally, the release of CER-1200 doesn't just benefit the patients, but the company's team of pharmaceutical researchers as well. The launch marks a significant milestone in their work, and such achievements motivate them to continue working on finding effective treatments for various diseases.The pharmaceutical company intends to make CER-1200 available to as many countries as possible to ensure that patients have access to the medication. The launch of this new drug is expected to have a significant impact on the medical community and the patients it serves.To ensure that CER-1200 is effective and safe, the pharmaceutical company has conducted rigorous clinical trials involving several test groups. The trials produced impressive results, indicating that CER-1200 is a potent medication that can help patients manage their symptoms. The clinical trials also showed that the medication is generally safe and well-tolerated.The pharmaceutical company involved in the development and launch of CER-1200 has a strong financial base that allows them to carry out extensive research and development. This foundation enables them to invest in cutting-edge technology, hire the best researchers, and create a conducive working environment that fosters innovation. The company's management believes that their investments, combined with successful product launches, will drive the company's growth for years to come.In conclusion, the pharmaceutical company responsible for CER-1200 has launched a drug that has the potential to revolutionize the treatment of a specific medical condition. The medication is safe, effective, and comes in various forms that cater to different patient needs. The launch of CER-1200 is a significant milestone for the company and marks its commitment to finding innovative treatments for various ailments. With the launch of this medication, patients struggling with this chronic condition have a renewed sense of hope that their symptoms can be managed effectively.