- Home

- Chemical Vapor Deposition

Chemical Vapor Deposition: A Comprehensive Guide to OEM Manufacturing

Introducing a cutting-edge technology for growing high-quality ceramics - Chemical Vapor Deposition (CVD). This technique involves the deposition of a thin layer of ceramic material onto a heated substrate in a vacuum environment. The process is highly reliable and yields high-purity, high-density ceramic films that can be used in various applications such as microelectronics, optoelectronics, and energy storage systems.

At Shandong Zhongpeng Special Ceramics Co., Ltd, a leading manufacturer, factory, and supplier in China, we excel in producing CVD ceramics that meet the most stringent requirements of our clients. Our team of experts has developed a range of CVD ceramic products with superior thermal conductivity, electrical insulation, and mechanical strength. These products are widely used in semiconductor and LED manufacturing, aerospace and defense industries, and other cutting-edge technologies.

Our commitment to innovation and quality in manufacturing CVD ceramics has established us as a trusted supplier in the global market. Contact us today to learn more about our CVD ceramic products and how we can help your business succeed.

SHANDONG ZHONGPENG SPECIAL CERAMICS CO., LTD

Company News

Related News

Spray gun tube, industrial ceramic tiles

Buy high-quality industrial ceramic tiles with our spray gun tube at our factory. Durable and efficient, our tiles are perfect for commercial and residential projects. Shop now and get great deals!

FGD Scrubber nozzle

Looking for high-quality FGD scrubber nozzles? Look no further than our factory! We provide top-notch products that are both efficient and durable. Order now and experience the best!

Reaction-bonded silicon carbide protecting pipe

Our factory produces high-quality Reaction-bonded silicon carbide protecting pipes for superior corrosion and wear resistance. Trust us for durable solutions.

Desulphurizing and dedusting nozzle

As a factory specializing in the production of desulphurizing and dedusting nozzles, we offer high-quality products designed to effectively remove hazardous particulate matter from industrial exhaust gases. Trust us for efficient and reliable air pollution control solutions.

Silicon Carbide Crucibles saggers- Application in the processing of high temperature corrosive powders

Looking for high-quality Silicon Carbide Crucibles and Saggers for processing corrosive powders at high temperatures? Look no further than our factory! We offer reliable and durable solutions that meet your needs. Order now and benefit from our top-notch products.

RBSiC (SiSiC) Beams

We are a factory specializing in production of high-quality RBSiC (SiSiC) Beams. Our products are finely crafted and excellent for industrial purposes.

Silicon carbide apex liner

As a factory, we offer the highest quality silicon carbide apex liners. Our products are durable and long-lasting, perfect for your industrial needs. Shop now! #siliconcarbide #apexliner #industrialproducts

Revestimiento del colector hidráulico-Silicon carbide liner - Carburo de Silicio

At our factory, we specialize in producing high quality hydraulic collector linings made from Silicon Carbide. Our products are durable and efficient, ensuring maximum performance. Find the perfect Revestimiento del colector hidráulico-Silicon carbide liner - Carburo de Silicio for your needs today.

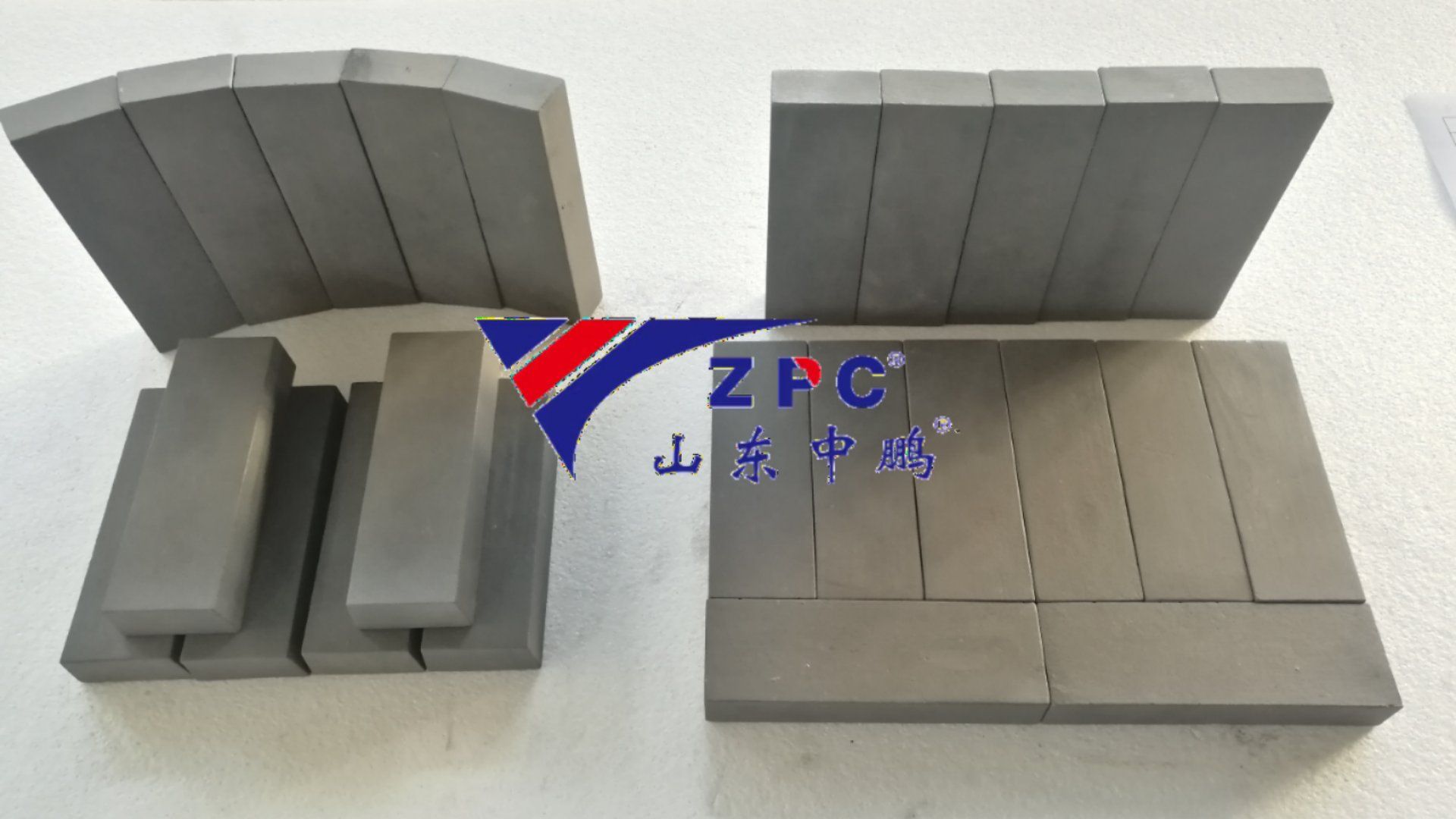

Wear-resistant silicon carbide ceramic tiles, liners and Alumina Ceramic Tiles Suppliers, Buyers,

As a leading factory producing wear-resistant silicon carbide ceramic tiles, liners, and alumina ceramic tiles, we offer top-quality products to buyers and suppliers. Contact us today!

Silicon carbide Beams and rollers

Looking for high-quality Silicon carbide beams and rollers? Look no further! Our factory is dedicated to producing top-notch products that withstand even the harshest of conditions. Guaranteed durability and reliability for your industrial needs.

DN50 Hollow Cone Narrow Angle

Looking for a DN50 Hollow Cone Narrow Angle product? Look no further than our factory! We specialize in producing high-quality products that will meet your needs. Contact us today to learn more. #DN50 #HollowCone #NarrowAngle #Factory #QualityProducts

RBSC-SiSiC burner nozzle

Looking for a high-quality RBSC-SiSiC burner nozzle? Look no further than our factory! Our products are expertly crafted to meet your needs. Order today!

liquid column nozzle

Looking for a reliable liquid column nozzle? Look no further than our factory. We offer top-quality products designed to meet your unique needs. Contact us today for competitive pricing and exceptional service.

wear resistant silicon carbide ceramic tiles

As a factory, we specialize in producing high-quality wear resistant silicon carbide ceramic tiles. Our durable and reliable products are perfect for industrial applications. Contact us today for more information.

Wear resiatant Silicon carbide ceramic liner

Looking for a reliable factory to provide quality wear-resistant Silicon carbide ceramic liners? Look no further! With our expertise, you can trust us to deliver high-performing products that meet your needs.

- Chemical Vapor Deposition: A Comprehensive Guide to OEM Manufacturing

- Reviews

- Related Videos

Introducing our cutting-edge technology for material deposition: Chemical Vapor Deposition. This revolutionary process allows for the creation of high-quality films and coatings on a variety of substrates. Our CVD system utilizes a gas phase process that ensures precise control over deposition parameters, resulting in uniform and reproducible coatings. With our CVD equipment, you can deposit a wide range of materials, including metals, ceramics, and alloys, all with exceptional purity and uniformity. The versatility of this technique makes it ideal for various applications in semiconductor processing, optical coatings, and advanced materials research. Our state-of-the-art CVD system is equipped with advanced features, such as atmospheric, low-pressure, and plasma-enhanced deposition modes. This allows for the fast and efficient deposition of single or multiple-layered coatings while maintaining high-quality results. Our CVD process is not only limited to research and development applications; it can also be scaled up for industrial scale production. This technique offers excellent reproducibility, superior uniformity, and precision for high-quality coatings on a large scale. In conclusion, our CVD system offers a reliable and effective solution for material deposition, making it an indispensable tool for high-tech industries. Give your research or production process a significant upgrade with our cutting-edge CVD technology.

Chemical vapor deposition is an innovative technology that produces high-quality coatings. I recently tried a chemical vapor deposition-based product and was extremely impressed with the results. The coating was extremely durable and resistant to wear and tear. The process was easy to use and resulted in a flawless finish. The quality of the product was evident in its superior performance and long-lasting durability. I highly recommend products using chemical vapor deposition technology for anyone that requires high-quality coatings for their materials.

Chemical Vapor Deposition technology has revolutionized the production of high-quality thin films with exceptional precision. I recently used a CVD system and was amazed by its speed and efficiency in creating uniform and highly controlled films. It offered excellent control over material composition, layer thickness, and morphology. The resulting films were of outstanding quality and had numerous unprecedented applications. Overall, the CVD technology is a wonderous form of thin film deposition and is an ideal solution for researchers and industries seeking cutting-edge advancements in materials science.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours