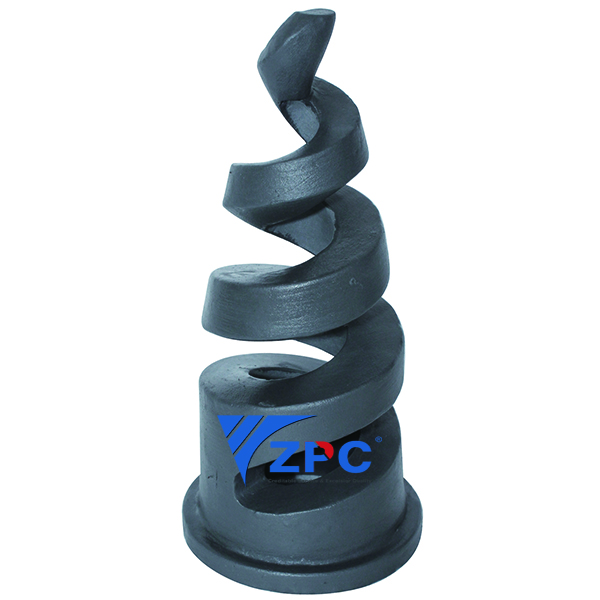

Silicon carbide burner nozzles are a kind of product with high strength, high hardness, high wear resistance,and good oxidation resistance, thermal shock resistance and other properties. RBSIC has more excellent long-term performance (Compared with RESIC and SNBSC) the bending strength is more than twice than RESIC, 50% high than SNBSC.

Reaction bonded silicon carbide ceramic applications:

The various industrial furnaces, the desulphurization equipment, the large boiers and other machinery , and the ceramics, the machinery ,the metallurgy, the electronics, the chemicals, the petroteum, the iron and steel industry, the military industry, the aviation industry and other fields.

Technical datasheet:

| Density | g/cm3 | 3.02 |

| Apparent porosity | % | <0.1 |

| Bending Strength | Mpa | 250(20℃) |

| Mpa | 280(1200℃) | |

| Modulus of Elasticity | Gpa | 330(20℃) |

| Gpa | 300(1200℃) | |

| Thermal Conductivity | W/m.k | 45(1200℃) |

| Thermal Explanation | k-1x10-6 | 4.5 |

| Vickers-hardness | Gpa | 20 |

| Acid-Proof Alikaline | Excellent |