Reaction bonded silicon carbide (RBSC) has excellent wear resistant peformance, good properties at elevated temperatures, good erosion and abrasive resistance, these properties can be utilised in a variety of applications such as pipe liners, ceramic elbow, spray nozzles, shot blast nozzles and hydrocyclone components.

Reaction bonded silicon carbide (RBSC) has excellent wear resistant peformance, good properties at elevated temperatures, good erosion and abrasive resistance, these properties can be utilised in a variety of applications such as pipe liners, ceramic elbow, spray nozzles, shot blast nozzles and hydrocyclone components.

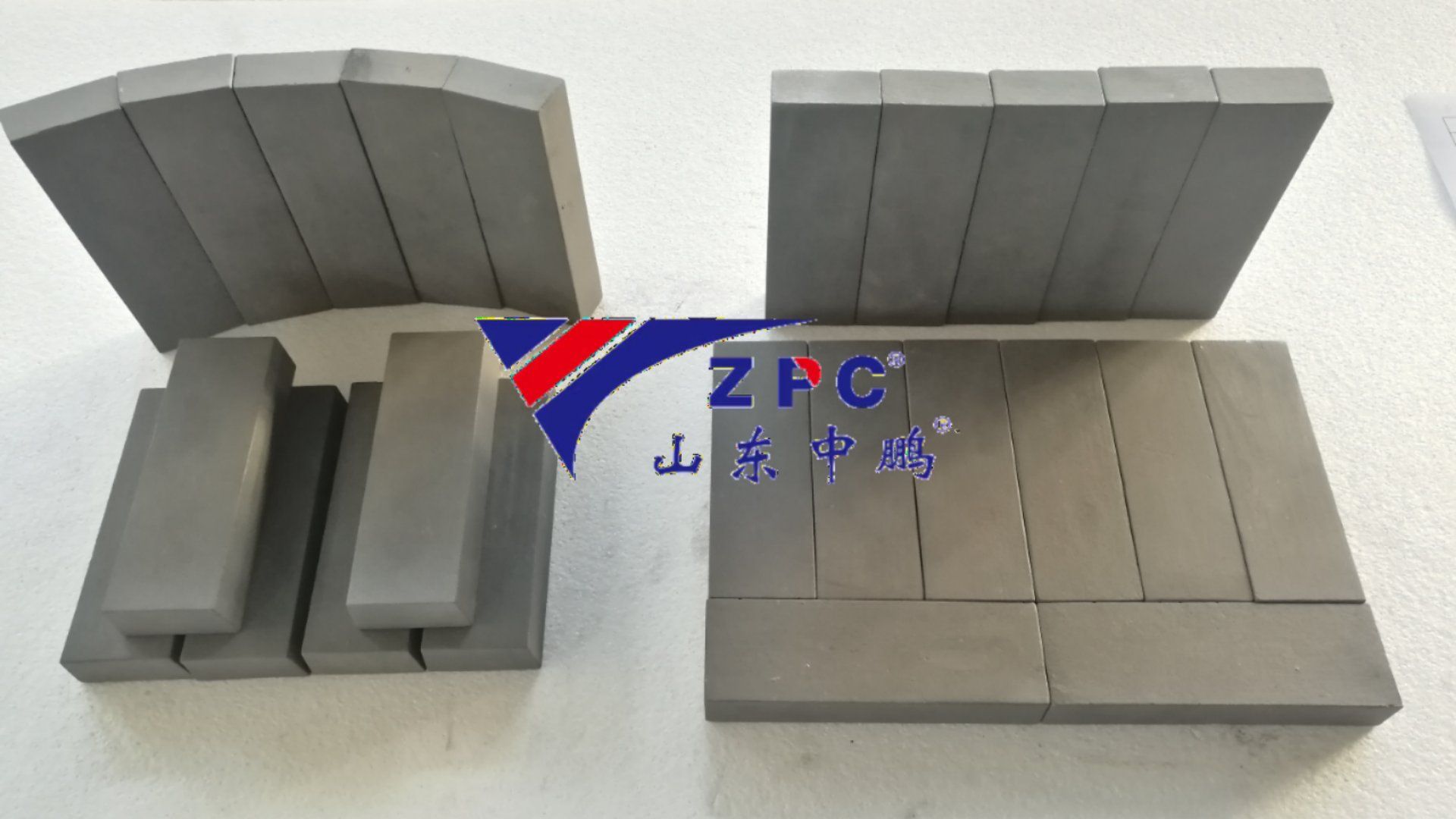

ZPC linings far outlast tiled and metallic liners. ZPC silicon carbide ceramics are thermal shock resistance and abrasion resistant which results in extended run times and reduced downtime. The reaction bonded silicion carbide ceramic ( RBSIC) is an ideal wear resistant material, which is especially suitable for the strong abrasive, coarse particles, classification, concentration, dehydration and other operations. Due to the above properties, the RBSiC / SiSiC silicon carbide liner elbow / liner tube can effectively protect the part from high wear and temperature so as to prolong the service life of the equipment.

ZPC linings far outlast tiled and metallic liners. ZPC silicon carbide ceramics are thermal shock resistance and abrasion resistant which results in extended run times and reduced downtime. The reaction bonded silicion carbide ceramic ( RBSIC) is an ideal wear resistant material, which is especially suitable for the strong abrasive, coarse particles, classification, concentration, dehydration and other operations. Due to the above properties, the RBSiC / SiSiC silicon carbide liner elbow / liner tube can effectively protect the part from high wear and temperature so as to prolong the service life of the equipment. | Technical Parameter Of Reaction-Bonded SiC Products | ||

| Item | Unit | Data |

| application temperature | °C | 1380 |

| density | g/cm3 | ≥3.02 |

| open porosity | % | ≤0.1 |

| bending strength | Mpa | 250(20°C) |

| Mpa | 280(1200°C) | |

| modulus of elasticity | GPa | 330(20°C) |

| GPa | 300(1200°C) | |

| thermal conductivity | W/(m·k) | 45(1200°C) |

| coefficient of thermal expansion | K-1×10-4 | 4.5 |

| rigidity | 9 | |

| acid & alkali resistance | excellent | |

Working condition of silicon carbide ceramic wear-resistant pipe

Typical silicon carbide characteristics include: Metallurgy and power industry: The reason why these two industries are put together is mainly because the two industries have a

- Low density

- High strength

- Good high temperature strength (Reaction bonded)

- Oxidation resistance (Reaction bonded)

- Excellent thermal shock resistance

- High hardness and wear resistance

- Excellent chemical resistance

- Low thermal expansion and high thermal conductivity

Typical silicon carbide applications include: They are used more for operation with wear at low temperature than for high temperature behavior. SiC applications are such as sandblasting injectors, automotive water pump seals, bearings, pump components, and extrusion dies that use high hardness, abrasion resistance, and corrosion resistance of carbide of silicon.

- Fixed and moving turbine components

- Seals, bearings, pump vanes

- Ball valve parts

- Wear plates

- Kiln furniture

- Heat exchangers

- Semiconductor wafer processing equipment