Reaction bonded silicon carbide (SiSiC or RBSIC) is an ideal wear resistant material, which is especially suitable for the strong abrasive,coarse particles, classification, concentration, dehydration and the other operations. It is widely used in mining industry, steel industry, coral processing industry, chemical industry, raw material-making industry, mechanical sealing, surface sandblasted treatment and reflector etc. Thanks to the excellent hardness and abrasive resistance, it can effectively protect the part where need wear protection, so as to prolong the service life of the equipment.

Reaction bonded silicon carbide (SiSiC or RBSIC) is an ideal wear resistant material, which is especially suitable for the strong abrasive,coarse particles, classification, concentration, dehydration and the other operations. It is widely used in mining industry, steel industry, coral processing industry, chemical industry, raw material-making industry, mechanical sealing, surface sandblasted treatment and reflector etc. Thanks to the excellent hardness and abrasive resistance, it can effectively protect the part where need wear protection, so as to prolong the service life of the equipment.  How to identify and find high-quality silicon carbide wear-resistant plates, tiles, liners? Silicon carbide wear-resistant tiles, liners, pipes are becoming more and more widely used in the mining industry. The following points are for your reference: 1. Formula and process: There are many SiC formulations on the market. We use authentic German formulations. In high-level laboratory tests, our product Erosion ㎝³ loss can reach 0.85 ± 0.01; 2. Hardness: SiC tiles are produced in ZPC: new Mohs hardness: 14.55 ± 4.5 (MOR, psi) 3. Density: ZPC SiC tile's density range is about 3.03+0.05.

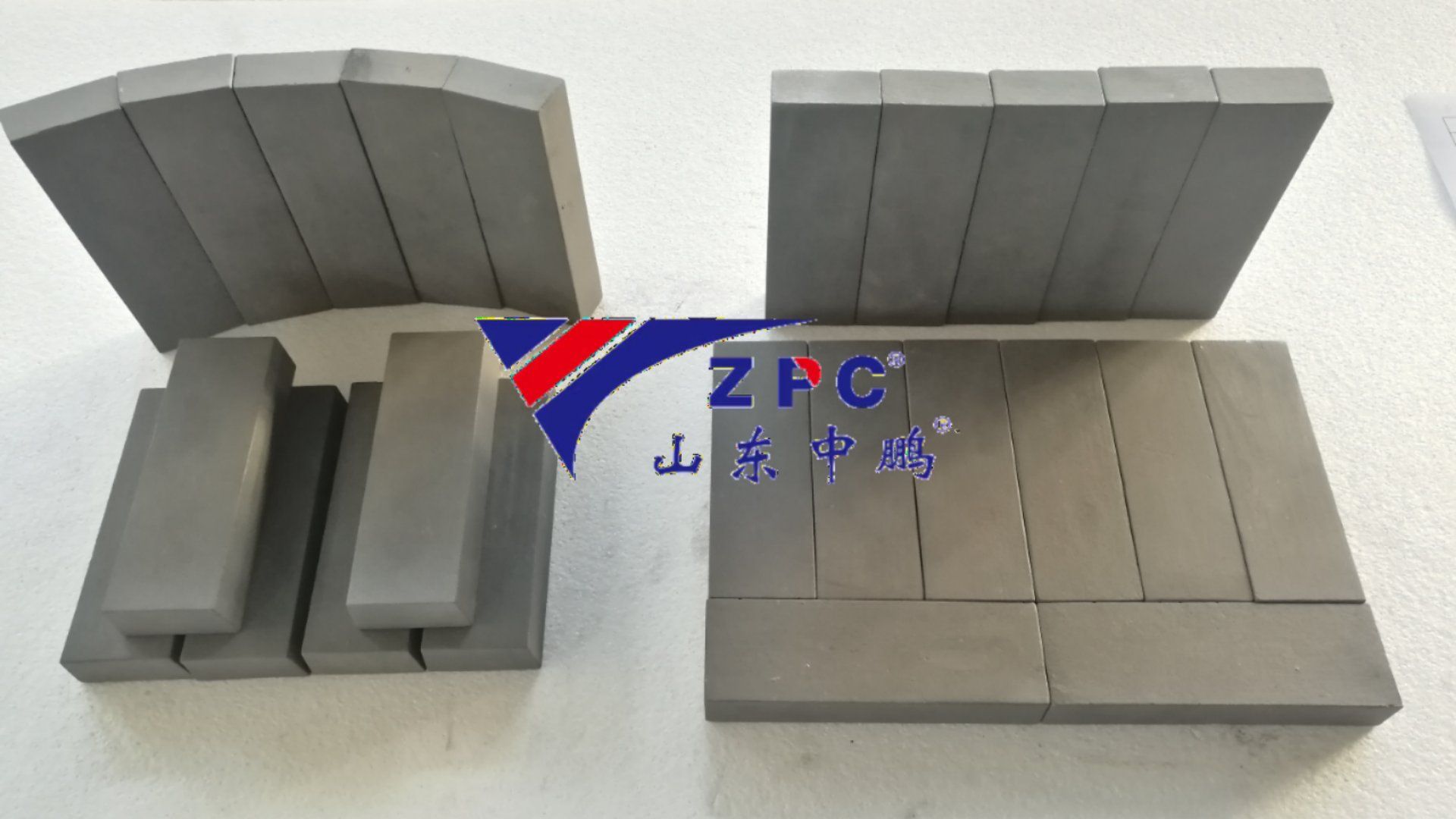

How to identify and find high-quality silicon carbide wear-resistant plates, tiles, liners? Silicon carbide wear-resistant tiles, liners, pipes are becoming more and more widely used in the mining industry. The following points are for your reference: 1. Formula and process: There are many SiC formulations on the market. We use authentic German formulations. In high-level laboratory tests, our product Erosion ㎝³ loss can reach 0.85 ± 0.01; 2. Hardness: SiC tiles are produced in ZPC: new Mohs hardness: 14.55 ± 4.5 (MOR, psi) 3. Density: ZPC SiC tile's density range is about 3.03+0.05.  4. Sizes and Surface: SiC tiles produced in ZPC without cracks and pores, with flat surfaces and intact edges and corners. 5. Internal materials: Silicon carbide wear-resistant liners/tiles have fine and uniform internal and external materials. If any questions, please feel free to contact us: [email protected] ■ Specifications:

4. Sizes and Surface: SiC tiles produced in ZPC without cracks and pores, with flat surfaces and intact edges and corners. 5. Internal materials: Silicon carbide wear-resistant liners/tiles have fine and uniform internal and external materials. If any questions, please feel free to contact us: [email protected] ■ Specifications: | Item | Unit | Data |

| Temperature of application | ℃ | 1380℃ |

| Density | G/cm3 | >3.02 |

| Open porosity | % | <0.1 |

| Bending strength -A | Mpa | 250 (20℃) |

| Bending strength -B | MPa | 280 (1200℃ ) |

| Modulus of elasticity-A | GPa | 330(20℃) |

| Modulus of elasticity -B | GPa | 300 ( 1200℃ ) |

| Thermal conductivity | W/m.k | 45 (1200℃ ) |

| Coefficient of thermal expansion | K-1 ×10-6 | 4.5 |

| Rigidity | / | 13 |

| Acid-proof alkaline | / | excellent |

■ Available Shape and sizes: Thickness: from 6mm up to 25mm Regular Shape: SISIC plate, SISIC Pipe, SiSiC Three Links, SISIC Elbow, SISIC Cone Cyclone. Remark: Other sizes and shape are available upon requests. ■ Packaging: In carton box, packed in fumigated wooden pallet with net weight 20-24MT/20'FCL. ■ Key benefits: 1. Excellent wear resistance, impact resistance and corrosion resistance; 2. Excellent flatness and excellent temperature resistance up to 1350℃ 3. Easy installation; 4. Longer service life (is about 7 times more than that of alumina ceramic and 10 times more than that of polyurethane Pattern of angle impact abrasion Low angle sliding abrasion When flow of abrasive material hits a wear surface at a shallow angle or passes parallel to it, the type of wear that occurs in friction is called sliding abrasion. Advanced silicon carbide ceramics provide wear resistance and corrosion resistance ceramic tiles and lining. These products have been proven wear of equipment in conveying, processing, and storage process. Our tiles can be produced with thickness from 8 to 45mm. it is important to ensure that you can get the required products. SiSiC: Moh's hardness is 9.5 (New Moh's hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion - resistance and anti-oxidation. It is 4 to 5 times stronger than nitride bonded silicon carbide. The service life is 5 to 7 times longer than alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. Wear resistant ceramic lining is conductive to make improvement of the production performance, the working efficiency, the reduction of maintenance costs and the increase profits. Precision ceramics have material knowledge, applied expertise and engineering skills. This can effectively ensure that the best solutions are offered to our customers. Silicon carbide ceramic tiles and lining are often used in applications such as cyclones, tubes, chutes, hoppers, pipes, conveyor belts and production systems. In the system, there are moving objects sliding on the surface. When the object slides on a material, it slowly wears the parts away until nothing remains. In high wear environments, this can happen frequently and cause a lot of expensive problems. The main structure is retained by using a very hard material, such as silicon carbide ceramics and alumina ceramics as a sacrificial lining. At the same time, silicon carbide ceramics can endure longer wear before it needs to be replaced, the silicon carbide ceramic service life is 5 to 7 times longer than alumina material . Wear Resistant Silicon Carbide Ceramic Tiles & Lining Properties: Chemical resistant Electrically insulative Mechanical erosion & Abrasion resistant Replaceable Advantages of Ceramic Wear Resistant Tiles & Linings: Can be used where tight tolerances or thin linings are required Can be used to resurface existing wear prone areas Can be used with multiple attachment methods like welding and adhesives Custom designed for specific applications Highly corrosion resistant Lightweight wear reduction solution Protects moving parts that are subject to high wear environments Significantly outlasts & outperforms wear reduction solutions Ultra-high maximum use temperature of up to 1380°C

■ Available Shape and sizes: Thickness: from 6mm up to 25mm Regular Shape: SISIC plate, SISIC Pipe, SiSiC Three Links, SISIC Elbow, SISIC Cone Cyclone. Remark: Other sizes and shape are available upon requests. ■ Packaging: In carton box, packed in fumigated wooden pallet with net weight 20-24MT/20'FCL. ■ Key benefits: 1. Excellent wear resistance, impact resistance and corrosion resistance; 2. Excellent flatness and excellent temperature resistance up to 1350℃ 3. Easy installation; 4. Longer service life (is about 7 times more than that of alumina ceramic and 10 times more than that of polyurethane Pattern of angle impact abrasion Low angle sliding abrasion When flow of abrasive material hits a wear surface at a shallow angle or passes parallel to it, the type of wear that occurs in friction is called sliding abrasion. Advanced silicon carbide ceramics provide wear resistance and corrosion resistance ceramic tiles and lining. These products have been proven wear of equipment in conveying, processing, and storage process. Our tiles can be produced with thickness from 8 to 45mm. it is important to ensure that you can get the required products. SiSiC: Moh's hardness is 9.5 (New Moh's hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion - resistance and anti-oxidation. It is 4 to 5 times stronger than nitride bonded silicon carbide. The service life is 5 to 7 times longer than alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. Wear resistant ceramic lining is conductive to make improvement of the production performance, the working efficiency, the reduction of maintenance costs and the increase profits. Precision ceramics have material knowledge, applied expertise and engineering skills. This can effectively ensure that the best solutions are offered to our customers. Silicon carbide ceramic tiles and lining are often used in applications such as cyclones, tubes, chutes, hoppers, pipes, conveyor belts and production systems. In the system, there are moving objects sliding on the surface. When the object slides on a material, it slowly wears the parts away until nothing remains. In high wear environments, this can happen frequently and cause a lot of expensive problems. The main structure is retained by using a very hard material, such as silicon carbide ceramics and alumina ceramics as a sacrificial lining. At the same time, silicon carbide ceramics can endure longer wear before it needs to be replaced, the silicon carbide ceramic service life is 5 to 7 times longer than alumina material . Wear Resistant Silicon Carbide Ceramic Tiles & Lining Properties: Chemical resistant Electrically insulative Mechanical erosion & Abrasion resistant Replaceable Advantages of Ceramic Wear Resistant Tiles & Linings: Can be used where tight tolerances or thin linings are required Can be used to resurface existing wear prone areas Can be used with multiple attachment methods like welding and adhesives Custom designed for specific applications Highly corrosion resistant Lightweight wear reduction solution Protects moving parts that are subject to high wear environments Significantly outlasts & outperforms wear reduction solutions Ultra-high maximum use temperature of up to 1380°C

1、 Iron and steel plant: 1, sintering machine drum mixer lining 2, drum wrapped ceramic rubber 3, fan impeller 4, disc feeder, dry material trough 5, coke hopper, converter bin, coke bin, cyclone dust collector. 2、 Power plant: 1. Ball mill outlet, mill volute, medium speed mill outlet, powder pipe elbow, cyclone dust collector, silo, hopper 2, coal hopper, coarse and fine powder separator, coal mill outlet, coal conveying hopper 3, coal hopper of bridge grab, center coal hopper of coal digger, outlet of ball mill, inlet and outlet of coarse and fine powder separator, volute of powder exhauster 4 Various kinds of direct current, swirl dense and dilute high temperature wear-resistant burners for coal-fired boilers; high-wear-resistant ceramic composite pipes and elbows, ceramic burners, ceramic fans, ceramic impellers, ceramic valves, etc.; various wear-resistant parts such as grinding balls, roller sleeves, grinding discs, disc tiles, grinding rings, nozzle balls and other wear-resistant parts for medium speed coal mills; pipes, wear-resistant damper and fans of various specifications for pulverizing and ash removal systems; balls All kinds of mill have (or not) bolt lining tile, lining plate, spiral pipe, gear ring, low chromium alloy steel ball, etc.; striking wheel, striking plate, guard hook, armor, separator, high temperature furnace flue gas pipe, etc. for fan coal mill; accessories required for various types of crushing machinery. 3、 Paper mill: 1. Pulverized coal pipe Main products and services: 1. Industrial wear-resistant ceramic pipes: all kinds of wear-resistant and high-temperature resistant ceramic lined with pulverized coal, tailings, slag slurry, slurry transportation pipeline, elbow, elbow, pulverized coal burner, coal mill outlet, coarse and fine powder cyclone separator, chute, hopper, storage bin, ore dressing barrel of mine magnetic separator; 2. Wear resistant ceramic fan: all kinds of high temperature resistant, wear-resistant, anti-corrosion fan impeller and volute, including centrifugal fan, axial flow fan, static blade, movable blade adjustable fan impeller, suction fan, powder exhauster, sintering fan, powder separation fan, dust removal fan, kiln head and kiln tail fan, etc; 3. Wear resistant ceramic lining pump and valve: ceramic lining, pump impeller, shell, baffle, pipe elbow, pneumatic ash removal and gas transmission valve and accessories of various slurry, slag slurry, mortar, tailings and other transportation systems. 4. Wear resistant ceramic coatings: all kinds of wear-resistant and high-temperature resistant ceramic coatings and mastic are used for fan volute, elbow pipe, mill outlet, coarse and fine separator pipe, chute, hopper and valve. 5. Wear resistant magnetic separation equipment: flow passage parts of various dry and wet mineral processing equipment, including magnetic separator drum, bottom groove, chute, pipeline, various mud pumps, slurry pump volute, impeller, and conveying pipeline. 6. Surface spraying technology: using the latest international inverter pulse arc power supply and high-speed arc spraying gun, various wear-resistant and anti-corrosion metal materials are sprayed on the metal substrate surface to form a wear-resistant and anti-corrosion protective layer. It can provide effective protection for all kinds of medium strength wear corrosion. Shandong Zhongpeng ZPC ceramics is an enterprise specializing in the production of industrial ceramics, mainly engaged in the R & D and production of silicon carbide ceramics. We can process ceramic products according to your drawings, specializing in the production of large size, high precision ceramic rod, ceramic pipe, ceramic ring, ceramic plate, ceramic flange, ceramic nozzle, and customized large size wear-resistant parts.

1、 Iron and steel plant: 1, sintering machine drum mixer lining 2, drum wrapped ceramic rubber 3, fan impeller 4, disc feeder, dry material trough 5, coke hopper, converter bin, coke bin, cyclone dust collector. 2、 Power plant: 1. Ball mill outlet, mill volute, medium speed mill outlet, powder pipe elbow, cyclone dust collector, silo, hopper 2, coal hopper, coarse and fine powder separator, coal mill outlet, coal conveying hopper 3, coal hopper of bridge grab, center coal hopper of coal digger, outlet of ball mill, inlet and outlet of coarse and fine powder separator, volute of powder exhauster 4 Various kinds of direct current, swirl dense and dilute high temperature wear-resistant burners for coal-fired boilers; high-wear-resistant ceramic composite pipes and elbows, ceramic burners, ceramic fans, ceramic impellers, ceramic valves, etc.; various wear-resistant parts such as grinding balls, roller sleeves, grinding discs, disc tiles, grinding rings, nozzle balls and other wear-resistant parts for medium speed coal mills; pipes, wear-resistant damper and fans of various specifications for pulverizing and ash removal systems; balls All kinds of mill have (or not) bolt lining tile, lining plate, spiral pipe, gear ring, low chromium alloy steel ball, etc.; striking wheel, striking plate, guard hook, armor, separator, high temperature furnace flue gas pipe, etc. for fan coal mill; accessories required for various types of crushing machinery. 3、 Paper mill: 1. Pulverized coal pipe Main products and services: 1. Industrial wear-resistant ceramic pipes: all kinds of wear-resistant and high-temperature resistant ceramic lined with pulverized coal, tailings, slag slurry, slurry transportation pipeline, elbow, elbow, pulverized coal burner, coal mill outlet, coarse and fine powder cyclone separator, chute, hopper, storage bin, ore dressing barrel of mine magnetic separator; 2. Wear resistant ceramic fan: all kinds of high temperature resistant, wear-resistant, anti-corrosion fan impeller and volute, including centrifugal fan, axial flow fan, static blade, movable blade adjustable fan impeller, suction fan, powder exhauster, sintering fan, powder separation fan, dust removal fan, kiln head and kiln tail fan, etc; 3. Wear resistant ceramic lining pump and valve: ceramic lining, pump impeller, shell, baffle, pipe elbow, pneumatic ash removal and gas transmission valve and accessories of various slurry, slag slurry, mortar, tailings and other transportation systems. 4. Wear resistant ceramic coatings: all kinds of wear-resistant and high-temperature resistant ceramic coatings and mastic are used for fan volute, elbow pipe, mill outlet, coarse and fine separator pipe, chute, hopper and valve. 5. Wear resistant magnetic separation equipment: flow passage parts of various dry and wet mineral processing equipment, including magnetic separator drum, bottom groove, chute, pipeline, various mud pumps, slurry pump volute, impeller, and conveying pipeline. 6. Surface spraying technology: using the latest international inverter pulse arc power supply and high-speed arc spraying gun, various wear-resistant and anti-corrosion metal materials are sprayed on the metal substrate surface to form a wear-resistant and anti-corrosion protective layer. It can provide effective protection for all kinds of medium strength wear corrosion. Shandong Zhongpeng ZPC ceramics is an enterprise specializing in the production of industrial ceramics, mainly engaged in the R & D and production of silicon carbide ceramics. We can process ceramic products according to your drawings, specializing in the production of large size, high precision ceramic rod, ceramic pipe, ceramic ring, ceramic plate, ceramic flange, ceramic nozzle, and customized large size wear-resistant parts.