High-quality Cutting Nozzles for Precision Cutting Applications

By:Admin

Victor Cutting Nozzle has been a pioneer in the cutting nozzle industry for over 100 years, and has established a reputation for producing high-quality cutting tools and equipment. The company is known for its innovative approach to product development and its commitment to providing customers with reliable and efficient cutting solutions.

The Victor 400 series cutting nozzle is the latest addition to the company’s extensive product lineup, and is expected to set a new standard for cutting nozzle performance. The nozzle features a precision-engineered design that allows for smooth and clean cuts, with minimal dross and distortion. Additionally, the Victor 400 series is capable of cutting a wide range of materials, including steel, stainless steel, aluminum, and other non-ferrous metals.

In a statement, a spokesperson for Victor Cutting Nozzle commented, “We are thrilled to introduce the Victor 400 series cutting nozzle to the market. This nozzle represents the culmination of years of research and development, and we believe it will revolutionize the way our customers approach cutting applications. We have designed the Victor 400 series to deliver unparalleled cutting performance, and we are confident that it will exceed the expectations of our customers.”

The Victor 400 series cutting nozzle is compatible with a variety of cutting systems and torches, making it a versatile and convenient choice for a wide range of industries. Whether used for industrial fabrication, automotive repair, or metalworking, the Victor 400 series is poised to become an essential tool for professionals who demand precision and reliability in their cutting operations.

One of the key features of the Victor 400 series cutting nozzle is its ease of use. The nozzle is designed to be simple and intuitive to operate, making it accessible to both seasoned professionals and novice users. This user-friendly design is complemented by the nozzle’s durable construction, which ensures longevity and consistent performance in demanding cutting environments.

The Victor 400 series cutting nozzle is also backed by the company’s renowned customer support and technical assistance. Victor Cutting Nozzle has a team of experienced professionals who are dedicated to helping customers maximize the performance of their cutting equipment. From product selection to troubleshooting, the Victor Cutting Nozzle team is committed to providing comprehensive support to ensure the success of its customers.

In addition to its technical expertise, Victor Cutting Nozzle is also known for its commitment to sustainability and environmental responsibility. The company’s manufacturing processes are designed to minimize waste and reduce the environmental impact of its operations. The Victor 400 series cutting nozzle is manufactured using advanced and environmentally friendly techniques, making it a responsible choice for customers who prioritize eco-friendly practices.

With the launch of the Victor 400 series cutting nozzle, Victor Cutting Nozzle continues to demonstrate its leadership in the cutting nozzle industry. The company’s dedication to innovation, quality, and customer satisfaction has positioned it as a trusted partner for professionals across a wide range of industries.

For more information about the Victor 400 series cutting nozzle and other cutting solutions offered by Victor Cutting Nozzle, please visit [company website] or contact [customer service information].

Overall, the Victor 400 series cutting nozzle is expected to set a new standard for performance and precision in the cutting nozzle industry, and it is poised to become an essential tool for professionals who demand reliability and efficiency in their cutting operations. With its innovative design, versatility, and user-friendly features, the Victor 400 series cutting nozzle represents a significant advancement in cutting technology and an exciting new option for cutting applications.

Company News & Blog

Durable Tiles: Discover Top Picks for Wear Resistant Flooring

Wear Resistant Tiles Revolutionize Industry SolutionsWear and tear are inevitable in industries that demand high levels of abrasion. It is a recurring problem that can lead to frequent equipment repair or replacement costs, significant downtime, and loss of productivity. But with the availability of wear-resistant tiles, these concerns can be minimized, if not eliminated.Wear-resistant tiles are ceramic or rubber tiles that are specifically designed to withstand high levels of abrasion and impact. These tiles are installed as liners, coatings, or coverings to protect equipment surfaces such as chutes, silos, hoppers, and conveyors. With their superior wear and impact resistance properties, these tiles are a cost-effective solution to enhance the lifespan of equipment surfaces and reduce maintenance downtime.One company that offers a complete range of wear-resistant tile solutions is (company name). With over (number) years of experience in the ceramic tiling industry, (company name) is one of the most trusted names in wear-resistant tiles. The company's wear-resistant tiles are manufactured with state-of-the-art technology, ensuring that they meet the highest standards of quality and durability.At (company name), customers can choose from a wide range of wear-resistant tile solutions that best fit their specific requirements. The company's ceramic wear-resistant tiles are made from high-purity alumina ceramics, which offer excellent wear and heat resistance properties. These tiles are perfect for applications that involve high temperatures, corrosive media, and heavy impact.The company also offers a range of rubber wear-resistant tiles that are ideal for impact and wear resistance in applications such as mining, cement, and power plants. These tiles are made from a blend of natural and synthetic rubber, which provides excellent anti-abrasion properties while remaining flexible to accommodate a wide range of surface profiles.(Company name) also offers custom-made wear-resistant tile solutions to meet the unique needs and demands of their clients. The company's team of highly skilled engineers and technicians work closely with clients to design and manufacture customized tiles that offer superior performance and longer service life than standard tiles.Aside from their high-quality products, what sets (company name) apart from their competitors is their commitment to providing exceptional customer support. The company offers comprehensive technical support and assistance, from the initial consultation and design stage to the final installation and maintenance of the tiles. They also offer on-site installation and training programs to ensure that clients can fully maximize the benefits of their wear-resistant tile solutions.With their exceptional product quality, customer support, and value for money, it's no surprise that (company name) has become the go-to partner of choice for businesses across various industries. The company has successfully served clients from all over the world, providing them with efficient, reliable, and durable solutions that have helped them improve their business operations and bottom line.In summary, wear-resistant tiles are a game-changer for businesses that require equipment surfaces to withstand high levels of abrasion and impact. With (company name)'s wide range of exceptional wear-resistant tile solutions, clients can enjoy longer service life, reduced maintenance costs, and increased productivity. Coupled with their world-class customer support, (company name) is a company that businesses can rely on to provide them with top-quality wear-resistant tile solutions that best meet their needs.

The Ultimate Guide to Flame Cutting Nozzles: A Comprehensive Analysis of 1-101 Nozzles

Flame Cutting Nozzle Revolutionizes the Cutting IndustryCutting industry technology just took a giant leap forward with the unveiling of the Flame Cutting Nozzle (#1-101). This new piece of equipment is changing the game for welders around the world.Flame cutting is a method of cutting metal that has been around for decades. Traditionally, this process involves using a torch to heat up a piece of metal until it's hot enough to cut through with a blade. This is a time-consuming process that requires a great deal of skill and expertise to master.The Flame Cutting Nozzle (#1-101) streamlines this process by reducing the amount of time it takes to cut through metal while increasing the precision and accuracy of the cut. This new nozzle is a must-have for any welder that needs to make precise cuts quickly.The Flame Cutting Nozzle works by using a combination of pressurized gases and plasma to generate an intense heat that melts through metal. This process is faster, safer, and more precise than traditional flame cutting methods.The nozzle itself is made from high-quality materials that are designed to withstand high temperatures and intense pressure. This ensures that it can be used repeatedly without losing its effectiveness.In addition to its cutting-edge technology, the Flame Cutting Nozzle is also incredibly easy to use. It can be easily attached to any standard torch and doesn't require any additional equipment or training. This makes it an excellent choice for welders of all levels of experience.The Flame Cutting Nozzle (#1-101) is produced by a leading manufacturer of welding equipment, who has been in the industry for over 50 years. The company has a track record of producing high-quality, reliable equipment that is trusted by welders around the world.This company is committed to providing the latest technology to their customers, which is why they invested heavily in the development of the Flame Cutting Nozzle. They spent years testing and refining the design, working closely with welders to ensure that it met their needs.Now that the Flame Cutting Nozzle is available to the public, welders around the world are taking notice. Many are already reporting significant improvements in their cutting speed and precision, allowing them to complete jobs faster and more efficiently than ever before.In addition to its benefits for individual welders, the Flame Cutting Nozzle also has the potential to transform entire industries. It could be used in manufacturing, construction, and even automotive repair, making these processes faster and more efficient.Overall, the Flame Cutting Nozzle (#1-101) is a game-changer for the welding industry. With its cutting-edge technology, ease of use, and reliability, it's quickly becoming a must-have for welders around the world. Whether you're a seasoned pro or just starting out in the industry, this nozzle is sure to revolutionize the way you work.

Leading Tube Factory Shares Exciting News

Ssic Tube Factory, a renowned manufacturer of high-quality tubes for various industrial applications, has announced impressive results in its latest financial report. According to the report, the company recorded a significant increase in sales revenue, profits, and market share in the past fiscal year. The news signals the company's continued growth and success in the highly competitive tube manufacturing industry.Ssic Tube Factory is a leading manufacturer of various types of tubes, including stainless steel tubes, titanium tubes, nickel alloy tubes, and many others, which are used in a wide range of industries, such as oil and gas, aerospace, automotive, chemical processing, and others. The company's mission is to provide its customers with the highest quality solutions, including customized products and superior technical support services.The company's impressive financial results are a testament to its relentless focus on innovation, quality, and customer satisfaction. According to the report, the company's sales revenue grew by nearly 20%, reaching a new record high, while its operating profit surged by more than 30%. The company's net profit also increased significantly, supported by its strong sales growth and cost optimization strategies.The company's outstanding performance in the past year has been driven by several factors, including its commitment to innovation and R&D investment. The company has continued to develop new products and solutions that meet the changing needs of its customers, such as the development of new corrosion-resistant tubes for the oil and gas industry. The company's investment in advanced technologies and production processes has also supported its growth, enabling it to deliver high-quality products with greater efficiency and cost-effectiveness.The company has also prioritized its customer-centric approach, focusing on providing superior technical support services, customization, and after-sales services. By doing so, it has been able to build strong relationships with its customers and deliver solutions that meet their specific needs. The company has also expanded its global footprint, reaching more markets and customers around the world, including Europe, America, and Asia.Furthermore, the company has put sustainability at the heart of its operations, implementing a range of environmental and social responsibility initiatives. These include reducing its carbon footprint, optimizing its energy and water consumption, and promoting fair labor practices and diversity in its operations. Such efforts have helped the company to build a strong reputation as a responsible and trustworthy partner among its customers, stakeholders, and communities.The company's success in the past year bodes well for its future prospects. The company's management is confident that it can continue to deliver sustainable and profitable growth, leveraging its strengths in R&D, technology, customer focus, and sustainability. The management has also identified various growth opportunities, such as expanding its product lines, entering new markets, and exploring new applications of its tubes in emerging industries.In conclusion, Ssic Tube Factory's impressive financial results in the past year demonstrate its strong capabilities as a leading manufacturer of high-quality tubes. Its commitment to innovation, quality, customer focus, and sustainability has enabled it to achieve significant growth and market success, despite the challenges posed by the global pandemic and the competitive industry landscape. The company's future outlook remains bright, supported by its strengths and growth opportunities in various areas. As such, the company is well-positioned to continue to deliver value to its customers, shareholders, and other stakeholders in the coming years.

Innovative Far Infrared Heating Element: The Latest Heating Technology Explained

In today's fast-paced world, technology plays a crucial role in improving our daily lives. From smartphones to smart homes, innovation is constantly shaping our future. One such innovation is the Far Infrared Heating Element, which has been gaining popularity in the heating industry due to its energy-efficient and eco-friendly nature.Far Infrared Heating Element, also known as FIR heating, is a revolutionary technology that utilizes the far infrared spectrum to emit heat. Unlike traditional heating methods, which rely on convection or conduction to transfer heat, FIR heating directly warms objects and individuals in its path. This results in a more efficient and comfortable heating experience, as the heat is evenly distributed throughout the space.The use of Far Infrared Heating Element has numerous benefits, making it an ideal choice for both residential and commercial settings. Firstly, FIR heating is energy-efficient, consuming less power compared to traditional heating systems. This not only helps in reducing energy costs but also contributes to a greener environment by lowering the carbon footprint. Additionally, FIR heating is known to improve air quality by reducing humidity and preventing the circulation of dust and allergens, making it a healthier option for indoor heating.One prominent player in the FIR heating industry is [Company Name]. The company has been at the forefront of developing cutting-edge heating solutions using Far Infrared Heating Element. With a strong focus on research and development, [Company Name] has built a reputation for delivering high-quality and innovative heating products that cater to the diverse needs of its customers.Established in [Year], [Company Name] has grown to become a leader in the heating industry, serving clients across the globe. With a state-of-the-art manufacturing facility and a dedicated team of engineers and technicians, the company has the capabilities to design and produce a wide range of FIR heating products for various applications. Whether it's heating panels for residential use or industrial heating solutions, [Company Name] prides itself on delivering reliable and efficient heating solutions that are built to last.One of the key factors that set [Company Name] apart from its competitors is its commitment to sustainability. The company understands the importance of minimizing its environmental impact and has integrated eco-friendly practices into its manufacturing processes. By using Far Infrared Heating Element, [Company Name] aims to promote energy conservation and reduce the reliance on traditional heating methods that contribute to greenhouse gas emissions.Furthermore, [Company Name] places a strong emphasis on customer satisfaction, offering personalized solutions to meet the unique requirements of each client. Whether it's designing custom heating systems or providing expert technical support, the company ensures that its customers receive the highest level of service and expertise.Looking ahead, [Company Name] is dedicated to further advancing the field of FIR heating through continuous innovation and research. By staying at the forefront of emerging technologies, the company aims to develop even more efficient and versatile heating solutions that will shape the future of the heating industry.In conclusion, Far Infrared Heating Element is a game-changing technology that is revolutionizing the way we heat our indoor spaces. With its energy-efficient and eco-friendly attributes, FIR heating is gaining traction as a preferred heating solution for homes, offices, and various other applications. As a leading innovator in this field, [Company Name] is paving the way for a sustainable and comfortable heating future.

Infiltrated SiSiC: A Breakthrough in Silicon Technology

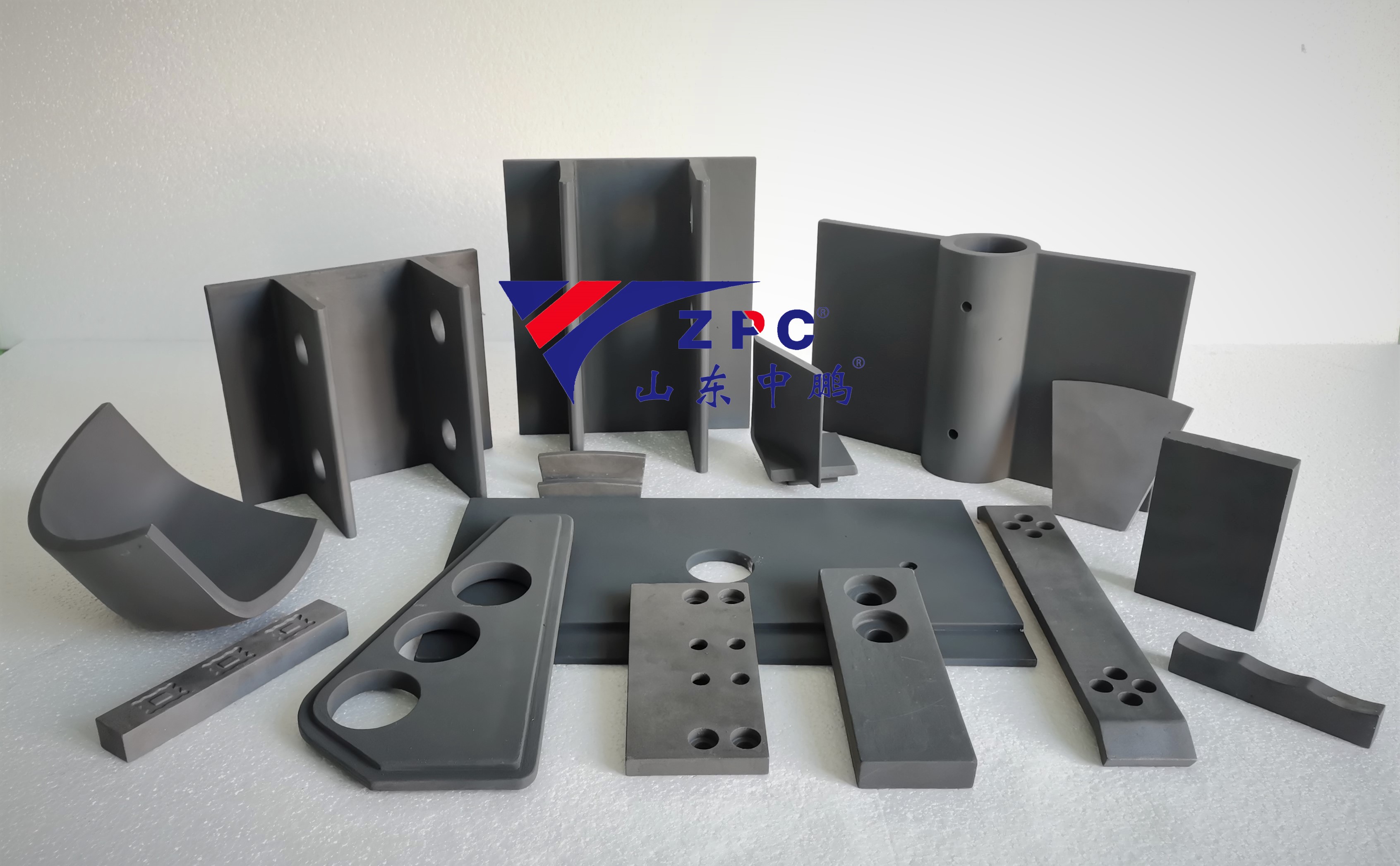

Silicon infiltrated Sisic (SiSiC) is a high-quality, high-temperature ceramic material that has gained widespread use in a variety of industrial applications due to its exceptional properties such as high strength, excellent thermal conductivity, and wear resistance. Its unique combination of properties makes it an ideal choice for use in a range of demanding environments, including aerospace, automotive, and chemical processing industries.One company that has been at the forefront of producing and supplying Silicon infiltrated Sisic (SiSiC) products is {}. With a strong focus on research and development, {} has become a leading provider of innovative SiSiC solutions for a wide range of applications. The company's commitment to quality, precision engineering, and customer satisfaction has cemented its reputation as a trusted partner for businesses seeking high-performance SiSiC components.The key to the exceptional performance of Silicon infiltrated Sisic (SiSiC) lies in its unique microstructure, which is achieved through a process known as silicon infiltration. During this process, molten silicon infiltrates the porous matrix of the material, resulting in the formation of a silicon carbide (SiC) ceramic with enhanced properties. The resulting SiSiC material exhibits high strength, excellent thermal shock resistance, and exceptional wear properties, making it an ideal choice for applications that require high-performance ceramic components.One of the key advantages of Silicon infiltrated Sisic (SiSiC) is its ability to maintain its mechanical properties at elevated temperatures, making it an ideal material for use in high-temperature environments. Its high thermal conductivity allows for efficient heat transfer, while its resistance to corrosion and oxidation ensures durability in harsh operating conditions. These properties make SiSiC an attractive choice for applications such as heat exchangers, radiant tubes, and kiln furniture, where reliability and performance are paramount.In addition to its mechanical and thermal properties, Silicon infiltrated Sisic (SiSiC) also offers excellent wear resistance, making it suitable for use in abrasive environments. Its exceptional hardness and toughness enable it to withstand the rigors of demanding industrial processes, making it an ideal choice for wear components such as nozzles, seals, and cutting tools. This makes SiSiC an attractive alternative to traditional materials such as metals and polymers, offering superior performance and extended service life.With a strong focus on quality and innovation, {} has developed a range of Silicon infiltrated Sisic (SiSiC) products tailored to meet the specific needs of its customers. Utilizing advanced manufacturing techniques and rigorous quality control processes, the company delivers high-performance SiSiC components that meet the highest standards of precision and reliability. Whether it is for use in aerospace, automotive, or chemical processing industries, {} works closely with its clients to develop customized SiSiC solutions that address their unique requirements.In conclusion, Silicon infiltrated Sisic (SiSiC) is a high-performance ceramic material that offers exceptional mechanical, thermal, and wear properties, making it an ideal choice for a wide range of industrial applications. With its proven track record of delivering innovative SiSiC solutions, {} continues to be a trusted partner for businesses seeking high-quality SiSiC components. As the demand for high-performance materials continues to grow, Silicon infiltrated Sisic (SiSiC) is poised to play a key role in shaping the future of advanced industrial applications.

Highly efficient electric radiant tube heater for effective heating in any space

Electric Radiant Tube Heaters Gain Popularity Among Industrial and Commercial UsersElectric radiant tube heaters have gained a lot of popularity in recent years due to their energy efficiency and effectiveness in providing even and comfortable heat in industrial and commercial settings. One of the leading companies in this industry, [Company Name], has been at the forefront of producing high-quality electric radiant tube heaters that have been widely embraced by businesses seeking efficient heating solutions.[Company Name] has been in the business of manufacturing electric radiant tube heaters for over 20 years. The company has built a strong reputation for producing top-notch heating solutions that are both reliable and cost-effective. Their electric radiant tube heaters are designed to deliver superior performance and energy efficiency, making them an ideal choice for a wide range of industrial and commercial applications.One of the key features of [Company Name]'s electric radiant tube heaters is their advanced heating technology. These heaters are equipped with high-quality heating elements that are designed to produce radiant heat, which is known for its ability to warm people and objects directly without heating the air. This makes electric radiant tube heaters an efficient heating solution, as they can provide warmth exactly where it is needed without any energy wastage.In addition to their advanced heating technology, [Company Name]'s electric radiant tube heaters are also highly durable and low maintenance. These heaters are constructed using high-quality materials and are built to withstand the rigors of industrial and commercial environments. With proper installation and regular maintenance, [Company Name]'s electric radiant tube heaters can provide many years of reliable and efficient heating.Another factor that has contributed to the popularity of electric radiant tube heaters is their environmental friendliness. Unlike traditional heating systems, electric radiant tube heaters do not produce any emissions, making them a clean and sustainable heating option. This is particularly important for businesses that are committed to reducing their environmental footprint and operating in a more sustainable manner.Furthermore, electric radiant tube heaters are known for their ability to provide even and comfortable heat distribution. This is due to their design, which allows them to emit radiant heat in a uniform manner, ensuring that the entire space is warmed evenly. This feature is particularly beneficial for large industrial and commercial facilities where maintaining a consistent and comfortable temperature is essential.With the rising demand for energy-efficient heating solutions, the market for electric radiant tube heaters is expected to continue growing. As businesses seek to reduce their energy costs and environmental impact, electric radiant tube heaters are likely to become an increasingly popular choice for heating industrial and commercial spaces.In conclusion, electric radiant tube heaters have become a popular heating solution for industrial and commercial users, thanks to their energy efficiency, even heat distribution, and environmental friendliness. [Company Name] has been a leading producer of electric radiant tube heaters for over two decades, offering high-quality and reliable heating solutions for a wide range of applications. As the demand for energy-efficient heating solutions continues to rise, electric radiant tube heaters are poised to play a key role in meeting the heating needs of industrial and commercial facilities.

Durable and High-Quality Technical Ceramic Taper Sleeve

Technical Ceramic Taper Sleeve: A Key Component in High-Performance MachineryIn the world of industrial machinery and equipment, precision and reliability are crucial factors. The performance of these machines can often be determined by the quality of the components used in their construction. One such component that plays a crucial role in the smooth functioning of machinery is the Technical Ceramic Taper Sleeve.Technical Ceramic Taper Sleeves are integral parts of various machinery used in industries such as automotive, aerospace, and manufacturing. These sleeves are known for their exceptional hardness, thermal stability, and resistance to corrosion, making them a popular choice for demanding applications.One company that has made a name for itself in the production of Technical Ceramic Taper Sleeves is {}. With a focus on precision engineering and quality manufacturing, {} has become a trusted name in the industry.{} is a leading manufacturer of technical ceramics, specializing in the production of high-quality components for industrial applications. With a reputation for excellence and a commitment to innovation, {} has established itself as a key player in the market.The Technical Ceramic Taper Sleeve produced by {} is designed to meet the stringent requirements of modern machinery. Made from advanced ceramic materials, these sleeves offer superior wear resistance and dimensional stability, ensuring long-term performance in the most demanding of environments.One of the key features of the {} Taper Sleeve is its exceptional thermal stability. In high-temperature applications, such as those found in the aerospace and automotive industries, thermal resistance is essential. The Technical Ceramic Taper Sleeve from {} is capable of withstanding extreme temperatures without compromising its performance, making it an ideal choice for these critical applications.In addition to its thermal stability, the {} Taper Sleeve also offers excellent hardness and wear resistance. This ensures that the sleeve can withstand the rigors of heavy-duty use, maintaining its integrity and performance over extended periods of time. This durability is a testament to the quality and precision manufacturing processes employed by {}.The corrosion resistance of the Technical Ceramic Taper Sleeve is another factor that sets it apart from conventional materials. Industrial machinery is often exposed to harsh chemicals and environments, which can lead to corrosion and degradation of components. The use of advanced ceramic materials in the construction of these sleeves ensures that they are impervious to corrosion, resulting in a longer lifespan and reduced maintenance requirements.With a focus on continuous improvement and innovation, {} is committed to pushing the boundaries of technical ceramic engineering. The company invests significantly in research and development, aiming to develop new and improved materials and manufacturing processes. This dedication to innovation ensures that {} remains at the forefront of the industry, offering cutting-edge solutions to its customers.In conclusion, the Technical Ceramic Taper Sleeve is a crucial component in the world of industrial machinery. Its exceptional properties, including thermal stability, hardness, and corrosion resistance, make it an indispensable part of high-performance equipment. With its focus on quality and innovation, {} has established itself as a leading manufacturer of these critical components, contributing to the efficiency and reliability of industrial machinery worldwide.

Exploring the Benefits and Applications of Radiant Tube Technology in Kilns

Radiant Tube of Kiln Transforms Cement IndustryInnovation in the manufacturing industry has always been a key driver of growth and progress. Recently, a breakthrough has been made in the cement industry, thanks to the Radiant Tube of Kiln. This invention has presented itself as a real game-changer in the industry, bringing a multitude of benefits that have transformed the way the industry operates today.One company that has made significant strides in this area is a global manufacturer that specializes in designing and manufacturing radiant tubes for various industrial applications. {} has been at the forefront of the transformation of the cement industry with its Radiant Tube of Kiln. The company has been developing this product for some time now, and the innovation has been well-received by cement producers worldwide.The Radiant Tube of Kiln is a heating element used in cement kilns to increase the temperature of the process. In essence, the radiant tube is a combustion tube containing a burner that heats up the interior of the tube. The process generates radiant heat that is then distributed through the tube's interior to the kiln, allowing manufacturers to process the cement with increased efficiency.One of the primary benefits of the Radiant Tube of Kiln is that it significantly reduces energy consumption. This is due to the unique design of the tube, which allows for a more efficient transfer of heat from the burner to the interior of the tube. This efficiency translates to cost savings for the manufacturing companies by reducing the costs of fuel and electricity used in the process.In addition, the Radiant Tube of Kiln has a longer lifespan than traditional tubes, further adding to the cost savings for companies. The tubes are built to withstand extreme temperatures and conditions, making them more durable over the long term. This longer lifespan not only reduces replacement costs but also offers a more sustainable alternative to traditional heating methods.The Radiant Tube of Kiln also has significant environmental benefits. The technology results in reduced emissions, making it an eco-friendly option for cement production. This is achieved through the tube's more efficient combustion process, which minimizes the release of particulate matter and greenhouse gases into the atmosphere.Moreover, the Radiant Tube of Kiln has presented manufacturers with improved process control. The tube has a uniform heat distribution system that provides better control over the cement production process. This allows manufacturers to produce high-quality cement consistently, reducing the risk of product defects, and improving overall quality. This increased control also lowers cement production costs, as any defects or issues in the process can be identified and resolved more efficiently.Since the Radiant Tube of Kiln's introduction to the market, it has been highly recommended by cement producers worldwide. The technology has been tested and proven by many manufacturers in various countries and has shown positive results. The Radiant Tube of Kiln has been able to meet the industry's needs for energy efficiency, quality, safety, and environmental protection, making it an essential part of the cement production process.This breakthrough technology has demonstrated the power of innovation, and businesses that leverage breakthroughs such as the Radiant Tube of Kiln will be more competitive in the market. For businesses that opt to implement the Radiant Tube of Kiln in their manufacturing processes, there are numerous benefits, including cost savings, improved quality, and a more environmentally responsible operation.In conclusion, the Radiant Tube of Kiln has transformed the cement industry, providing companies with a faster, more efficient, and eco-friendly process. {} has been instrumental in developing this technology, with a keen focus on quality, safety, and sustainability. With the Radiant Tube of Kiln, the cement industry is poised to enter a new era of efficiency and productivity.

New Technology: The Benefits of Quartz Infrared Heaters

As temperatures drop and colder weather sets in, many people are looking for ways to stay warm and cozy indoors. One popular option that is gaining traction is the use of quartz infrared heaters. These innovative heaters use advanced technology to provide efficient and effective heating for homes and businesses.Quartz infrared heaters are known for their ability to quickly and evenly heat a space. Unlike traditional heaters, which rely on convection to circulate warm air, infrared heaters work by emitting infrared radiation that directly heats objects and people in the room. This means that they can provide instant warmth, without the need to wait for the air to heat up. This makes them particularly well-suited for use in drafty or poorly insulated spaces, where traditional heaters may struggle to maintain a comfortable temperature.One company that has been at the forefront of the quartz infrared heater market is {}. With a long history of innovation and a commitment to quality, {} has become a leading name in the heating industry. The company’s quartz infrared heaters are known for their reliability, energy efficiency, and impressive heating capabilities.{} offers a wide range of quartz infrared heaters, suitable for various applications and spaces. Their heaters are designed to be both functional and stylish, with sleek and modern designs that can complement any décor. Whether you need a small heater for a personal office or a larger unit to heat a communal space, {} has a heater that will meet your needs.Another key feature of {}'s infrared heaters is their energy efficiency. By using infrared radiation to directly heat objects, rather than wasting energy trying to heat the air, these heaters can provide significant cost savings on energy bills. This makes them a popular choice for environmentally-conscious consumers who want to reduce their carbon footprint without sacrificing comfort.In addition to their energy efficiency, {}'s quartz infrared heaters are also designed with safety in mind. Many models are equipped with advanced safety features, such as overheat protection and tip-over switches, to prevent accidents and ensure peace of mind for users.The company also offers a high level of customer support, with knowledgeable representatives who can assist with product selection, installation, and troubleshooting. This level of service has helped {} build a loyal customer base, who praise the company for its commitment to quality and customer satisfaction.As the demand for energy-efficient and effective heating solutions continues to grow, the market for quartz infrared heaters is expected to expand. With their proven track record of performance and innovation, {} is well-positioned to remain a leader in this market and continue providing customers with top-of-the-line heating solutions.In conclusion, quartz infrared heaters are a popular and effective option for heating homes and businesses. With their ability to quickly and evenly heat a space, as well as their energy efficiency and safety features, it's no surprise that they are becoming an increasingly popular choice for consumers. As a leading manufacturer in this space, {} has been instrumental in driving the growth of the quartz infrared heater market, and is well-positioned to continue meeting the needs of customers for years to come.

Steel Plant Burner Nozzle: An Essential Component for Efficient Operations

Steel Plant Upgrades Burner Nozzle for Improved Efficiency and Environmental ImpactWith a commitment to continuous improvement and sustainability, the renowned steel plant {} has recently announced the implementation of a new and more efficient burner nozzle in its production processes. This upgrade is expected to not only enhance the plant's operational efficiency but also contribute to reducing its environmental footprint.The newly upgraded burner nozzle is designed to optimize the combustion process, resulting in higher thermal efficiency and lower energy consumption. By using advanced technology and innovative engineering, the plant aims to improve the overall production process while minimizing waste and emissions."As a leading steel manufacturer, we are constantly seeking ways to enhance our operations and minimize our environmental impact," said a spokesperson from {}. "The installation of the new burner nozzle is an important step towards achieving these goals, and we are excited about the potential benefits it will bring to our plant."The upgraded burner nozzle is expected to deliver several key benefits to the steel plant. One of the primary advantages is its ability to provide a more stable and controlled flame, which can lead to better heat distribution and reduced energy usage. This, in turn, can result in significant cost savings for the plant while also reducing its carbon footprint.Furthermore, the new burner nozzle is designed to minimize the formation of harmful by-products during the combustion process. By optimizing the air-fuel mixture and temperature distribution, the plant can reduce the generation of pollutants such as nitrogen oxides and particulate matter, contributing to improved air quality in the surrounding area.The implementation of the new burner nozzle aligns with the company's broader commitment to sustainability and environmental stewardship. Recognizing the importance of responsible production practices, {} has been actively investing in technologies and initiatives aimed at reducing its environmental impact and promoting sustainable manufacturing processes.In addition to the upgrade of the burner nozzle, the steel plant has also been exploring other innovative solutions to enhance its overall efficiency and sustainability. This includes the adoption of advanced recycling techniques, the utilization of renewable energy sources, and the implementation of more efficient production methods."We are dedicated to integrating sustainable practices into every aspect of our operations," the spokesperson continued. "Our investment in technologies like the new burner nozzle reflects our ongoing commitment to minimizing our environmental footprint and operating as a responsible corporate citizen."The implementation of the new burner nozzle is expected to have a positive impact not only on the steel plant itself but also on the broader community and environment. By improving energy efficiency and reducing emissions, the plant is taking important steps towards contributing to a more sustainable and environmentally friendly steel production industry.As the steel plant continues to prioritize sustainability and innovation, it remains committed to exploring new opportunities for improvement and setting higher standards for environmental performance within the industry. The installation of the new burner nozzle is just one example of the plant's dedication to embracing cutting-edge technologies and sustainable practices to drive positive change in the steel manufacturing sector.In conclusion, the upgrade of the burner nozzle in the steel plant reflects the company's unwavering commitment to driving operational excellence and sustainability. By adopting advanced technologies and investing in innovative solutions, {} is demonstrating its proactive approach to enhancing efficiency, reducing environmental impact, and setting new benchmarks for responsible manufacturing practices. Through initiatives like the implementation of the new burner nozzle, the steel plant is paving the way for a more sustainable and environmentally conscious future in the steel industry.